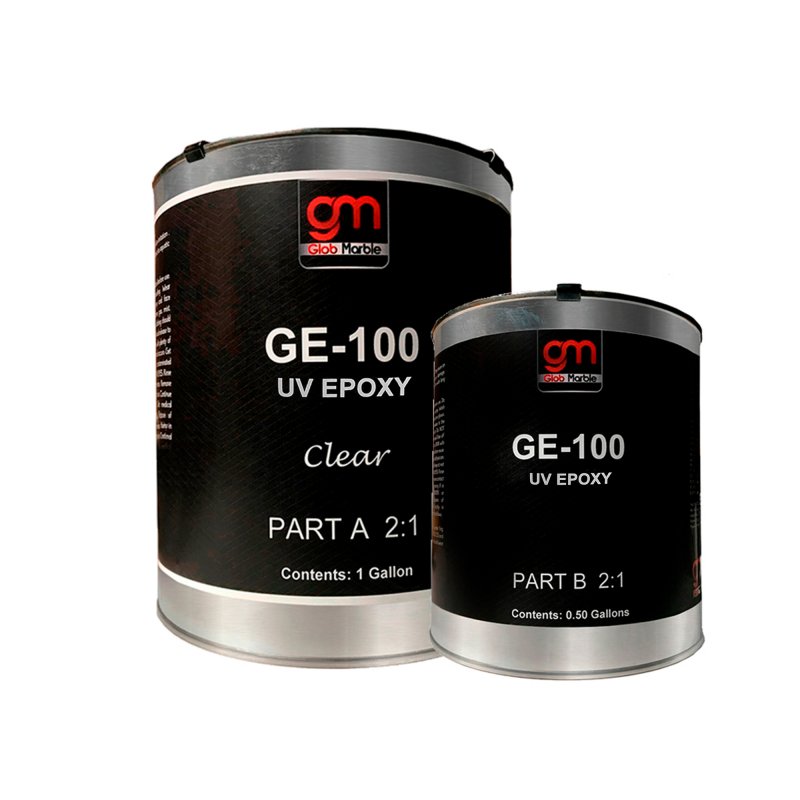

Epoxy Floor Coating GE-100 Clear. 100% Solids

GE-100 Epoxy — 100% Solids, UV-Resistant Formula

GE-100 is a professional-grade, 100% solids epoxy floor coating for metallic epoxy floors, solid-color epoxy systems, epoxy flake systems, and decorative chip/quartz builds. Its advanced formulation provides excellent UV resistance with reduced yellowing, maintaining clarity and gloss in bright, sun-lit interiors. The low-odor, low-VOC application profile makes it a strong choice for garage floor epoxy upgrades and industrial epoxy flooring in active facilities (For maximum UV resistance, finish with a UV-stable aliphatic urethane or polyaspartic topcoat).

Technical Specifications

- Recommended thickness: 16–18 mils

- Coverage per gallon: ~65–100 sqft (varies by surface profile & method)

- Finish: High Gloss

- Mix ratio (by volume): 2:1 Parts A&B

- Packaging: 1.5-gal kit, 3-gal kit, 15-gal kit

Why installers choose GE-100

- Clarity & gloss that last — strong resistance to ambering under ambient UV.

- High-build body — lays down 16–18 mils in one pass for depth and metallic movement.

- Versatile — pigmented basecoat/primer, High build epoxy for metallic, pigmented, and flake systems, and binder for chips & colored sand.

- Safe for homes — low-odor/low-VOC handling suitable for occupied garages, basements, shops, and industrial spaces with ventilation.

Recommended uses:

Restrooms • Commercial Kitchens • Warehouses • Retail • Showrooms • Basements • Residential Garages • Laundry Rooms • Industrial epoxy flooring projects requiring a high-build epoxy.

Product Instructions:

Surface prep

- Cure: All epoxy and resinous systems require a minimum concrete age of 28 days. For freshly poured concrete, wait a minimum of 28 days before beginning system application.

- Moisture: Concrete substrates with an underlying moisture issue may require a moisture vapor barrier. To check if your concrete has a moisture issue, a simple method is the plastic sheet test. Tape a 4" x 4" plastic sheet to the floor and wait 24 hours. If condensation appears under the plastic sheet, further moisture diagnosing may be required.

- Profile: Diamond-grind or shot-blast to CSP-2/3. This is recommended for maximum bond strength, and to avoid system delamination.

- Patch: All concrete surfaces must be sound, and flush. All imperfections like hairline cracks and large voids must be patched with a suitable concrete patcher like GCF.

- Clean: Vacuum concrete substrate to remove dust from grinding process and any other remaining contaminates.

- Prime: Either use GE-C10W water-based epoxy primer, or use the GE-100 UV epoxy itself as a primer. The prime coat closes the pores of the concrete to prevent off-gassing, and ensures a good bond to the substrate. Pigmented primers also color the substrate for metallic, pigmented, or flake systems.

- Sand: Screen the primer coat with a 100 grit sanding screen on a rotational floor machine. This screening will ensure not only a good bond between coats, but also eliminate any debris or dust that may have settled onto the preceding coat as it was curing. Follow screening with vacuuming. Follow vacuuming with a micro-fiber wipe with a solvent such as xylene or acetone.

Mixing & Handling

- Premix: Pre-mix Part A. If using solid or metallic pigments, premix the pigment into the Part A in this step.

- Proportion: Precisely measure 2:1 parts A&B by volume in a measuring container. Use the pre-measured kits as supplied whenever possible.

- Mix: Combine 2 Parts A and 1 Part B in a bucket. Blend with a low-speed paddle mixer for approximately 3 minutes until fully uniform with no streaks (avoid entraining air).

- Bucket Transfer: Transfer the mixed material to a clean pail and mix briefly again to avoid using unmixed epoxy stuck to the walls of the original bucket.

- Place immediately: As soon as Parts A & B are catalyzed, pour onto the floor right away. Material left in the pail will accelerate cure and reduce working time.

- Warning: Do not flip the pail to "drain"; any unmixed residue on the sidewalls can potentially create soft/uncured spots on the floor.

Product Application

- Footwear: Wear spiked shoes for the entire application. Spike shoes prevent you from leaving footprints in wet epoxy.

- Application: Apply GE-100 with magic trowel squeegee, roller, or V-notch squeegee.

- Build: Lay to 16–18 mils total thickness per coat. For easy application, pre-mark the wall with blue painter’s tape at measured intervals that match your kit’s target square-foot coverage.

- Backroll or Texture: For all non-metallic applications (primer/base, solid-color epoxy, flake/chip systems, or quartz/sand broadcasts), back-roll immediately in perpendicular passes to level the epoxy, remove squeegee lines, and get consistent thickness of material. For metallic epoxy, texture the epoxy with a roller or squeegee for a more natural looking metallic pigment distribution.

- Broadcast: For broadcast systems like flakes, chips, quartz or other media, broadcast while wet. Always broadcast in a "chicken feeding" motion, throwing the broadcast up into the air and allowing it to fall onto the fresh GE-100.

- Cure: tack free (dry to touch) ~6 - 10 hours, recoat or topcoat ~10 - 16 hours, light foot traffic ~16 - 24 hours, full cure (heavy traffic ~3 - 7 days).

- Conditions: Keep temperature and relative humidity within recommended ranges during application and cure (see TDS).

Recoat / Topcoating

- 10-16 Hours Later: Recoat or topcoat only after the coat is tack-free (dry to touch in ~6–10 hours) and within the recoat window (typically 10–16 hours; see TDS for conditions). Note: colder temperatures extend cure times and may push the recoat window later.

- After 12-24 Hours: If more than ~12–24 hours have passed, or if dust/debris has settled, the GE-100 needs a mechanical bond for proper sealer adhesion. Screen the surface with a 100-grit sanding screen on a floor buffing machine, then vacuum thoroughly and wipe with denatured alcohol using a clean microfiber cloth.

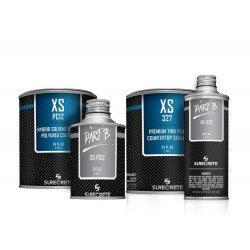

- Topcoat Choices (for UV and wear protection):

- GU-20: solvent-based polyurethane (gloss and satin finish)

- GU-30: solvent-based polyurethane with grip additive (orange-peel finish)

- GU-20WB: water-based polyurethane (gloss and flat finish)

- GP-20: super fast setting polyaspartic (gloss finish)

Restrictions:

Keep floor use at a light traffic and use non-harsh chemicals until the coating is fully cured (see technical data under full cure). It is best to keep the floor dry for the full cure cycle. Caution: surface may be slippery, especially when contaminated or wet; keep surface clean and dry.

Frequently Asked Questions

Q: What’s the coverage?

A: For metallic floors, plan a maximum of about 65 sqft per gallon. For pigmented epoxy, flake/chip, or primer coats, plan up to about 100 sqft per gallon. Actual coverage varies by surface profile and technique.

Q: Is it suitable for garage floors?

A: Yes, GE-100 is frequently used as garage floor epoxy thanks to its low-odor/low-VOC application and durable, high-build finish. For best hot-tire and UV performance, topcoat with polyurethane or polyaspartic.

Q: Can it be used outside?

A: Typically not recommended. It’s still an epoxy and can yellow with UV over time. The only exterior use we suggest is a heavy flake broadcast that fully covers the epoxy, finished with one of our UV-resistant sealers.

Q: Does it yellow?

A: All epoxies can amber with UV, but GE-100 provides excellent UV resistance and reduced yellowing for long-term clarity indoors. For sun-exposed areas, use a UV-stable polyurethane or polyaspartic topcoat.

Q: When can I recoat or topcoat?

A: Recoat/topcoat after tack-free (about 6–10 hours). If more than 12–24 hours have passed, or dust/debris has settled, screen with 100-grit, vacuum, and wipe with denatured alcohol before recoating.

Q: Does GE-100 work for industrial floors?

A: Yes, its 100% solids body, chemical resistance (see TDS), and quick build make it well-suited for industrial epoxy flooring systems.

Q: What primer should I use?

A: Use GE-C10W water-based epoxy primer for best pore-closing and color uniformity, or use GE-100 itself as a primer on properly prepared concrete.

Q: Do I need a moisture vapor barrier?

A: If the slab shows moisture issues (e.g., condensation under a taped plastic sheet after 24 hours or elevated RH/MVER tests), use an appropriate moisture vapor barrier before GE-100. When in doubt, test or consult a flooring professional.

Q: Can I apply GE-100 over an existing coating?

A: Yes, if the existing coating is sound and compatible. Clean, degloss with a 100-grit screen, vacuum, and solvent-wipe before application. If chemistry is unknown, do an adhesion test patch first.

Q: How do I get slip resistance?

A: The most reliable way to make epoxy slip resistant is to use the GU-30 polyurethane topcoat. It gives has a grip additive inside which will prevent slipping, and give the epoxy a orange peel finish.

Q: Is GE-100 low-VOC/low-odor?

A: Yes, GE-100 is low-odor and low-VOC, suitable for occupied garages, basements, shops, and many industrial spaces with proper ventilation.

Q: Can GE-100 be used as a basecoat/primer?

A: Yes, use it clear for clear epoxy floors. Use it with epoxy pigment for metallic, flake, and solid pigment systems.

Q: What cleaners should I use after cure?

A: Use pH-neutral cleaners. Some harsh cleaners or strong solvents can affect appearance — test in a small area first.

-175x175.jpg)