-550x550w.jpg)

-80x80w.jpg)

- Stock: In Stock

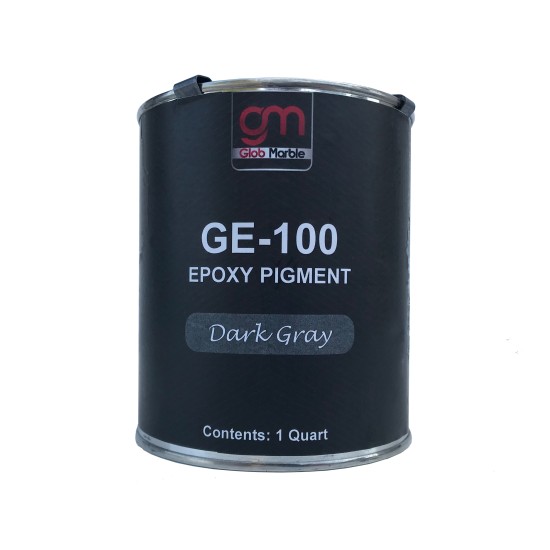

- Model: GE-100P

Available Options

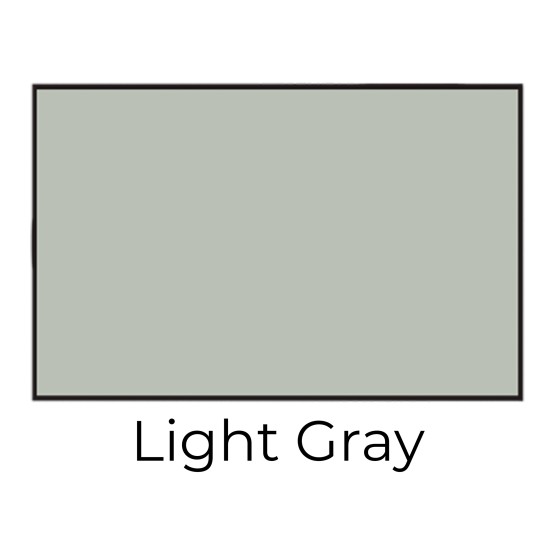

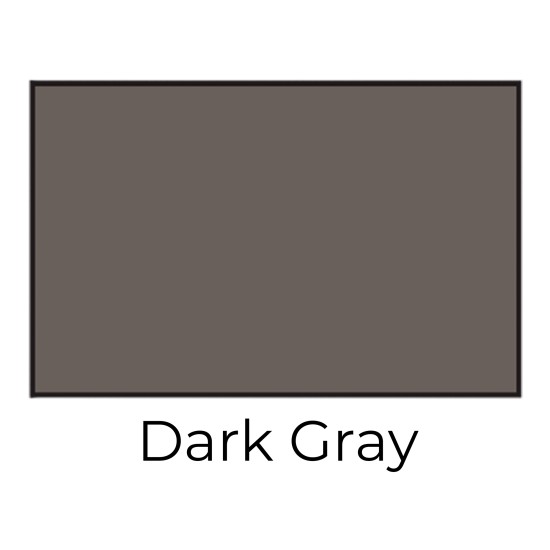

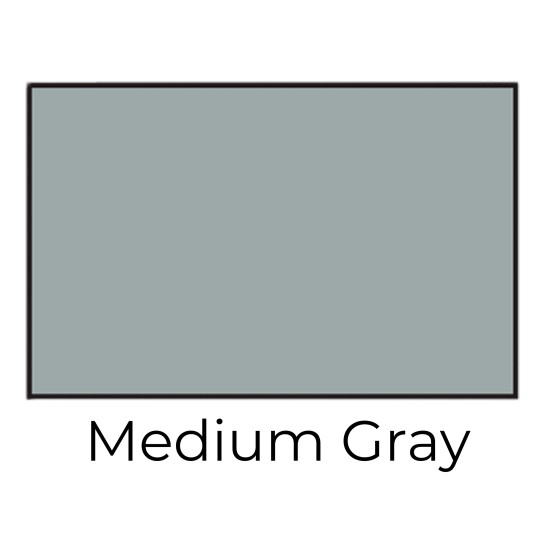

Liquid Pigments for GlobMarble GE-100 Epoxy 100% .

PACKAGING INFORMATION

1 quart

MIX RATIO:

1 quart for 3 gallon kit of GE-100 Epoxy Clear

MIXING AND HANDLING:

Kits of this product should be mixed in their entirety. Add GE-100 Pigment to part A clear GE-100 epoxy. Mix part A and pigment with mechanical mixer for 3 minutes at medium speed for pigment dispersal. Pour part B to part A and mix with mechanical mixer with medium speed for 3 minutes. If using partial kits, refer to the technical data instructions for this product for proper weight mix ratios. After the two parts of the product are combined, mix with slow speed mixing equipment until the material is thoroughly mixed and streak free. Once A & B parts are mixed, the catalyzed GE-100 epoxy should be placed on floor immediately. Left epoxy in pail will cure at accelerated rate. Do not leave pail upside down to drain onto floor. Any un- mixed portion of A or B that may have accidentally been placed onto side of pail can now drain down onto the floor, creating a spot that will not cure. Please refer to the GE-100 epoxy technical data for proper application and instructions.

Pigmented Epoxy may be applied as thick build for decorative concrete materials, a primer coat for 3D metallic systems, epoxy flakes paint chips.

GlobMarble GE-100 seamless epoxy coating recommended for restrooms, warehouses, kitchens, and any other areas where either a high build layered clear product is needed, or for any decorative filled floor.

Please leave a review

Write Review

-320x320w.jpg)