- Stock: In Stock

- Model: 8084MR01

Available Options

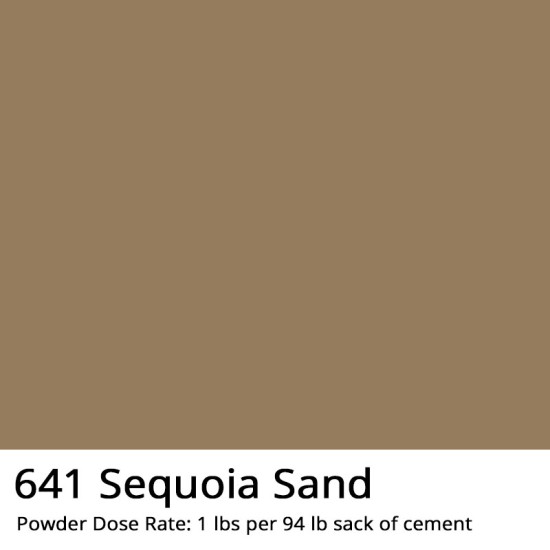

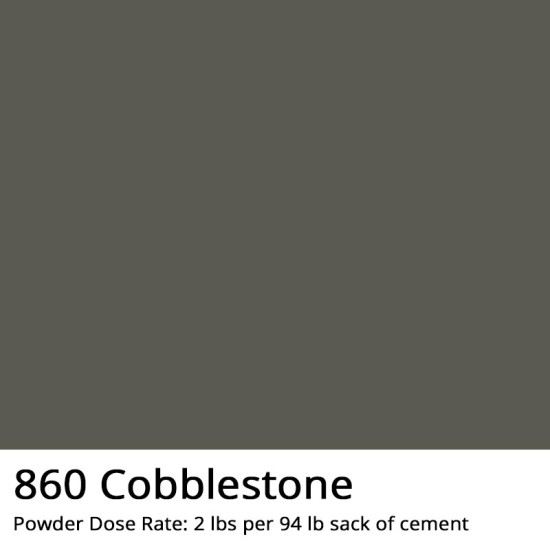

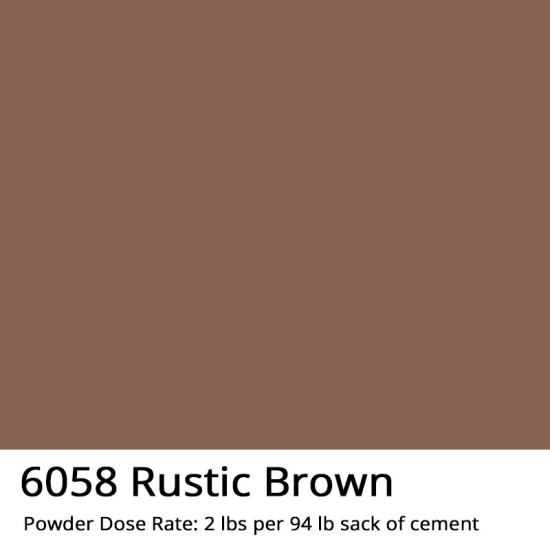

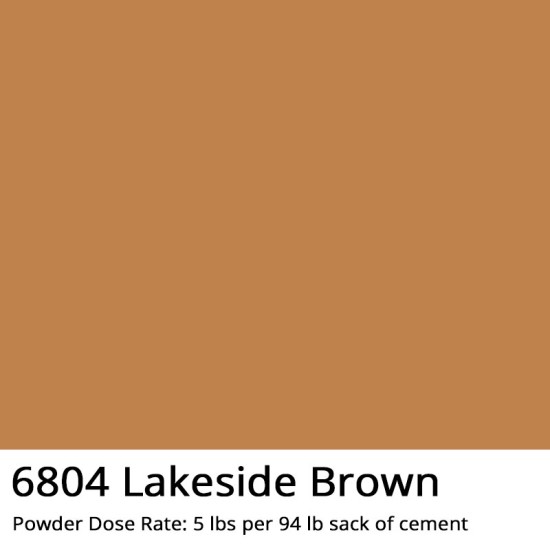

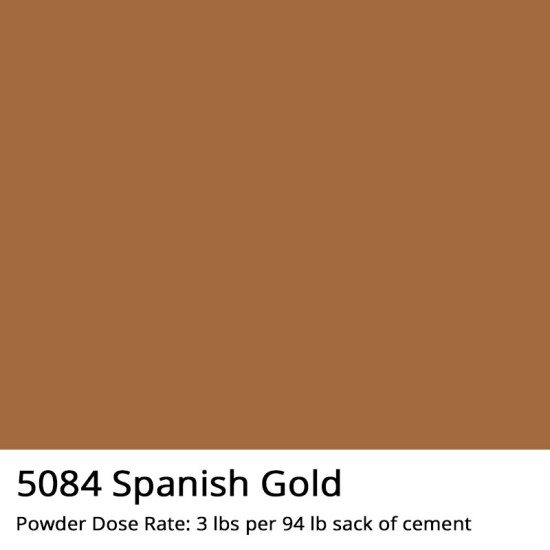

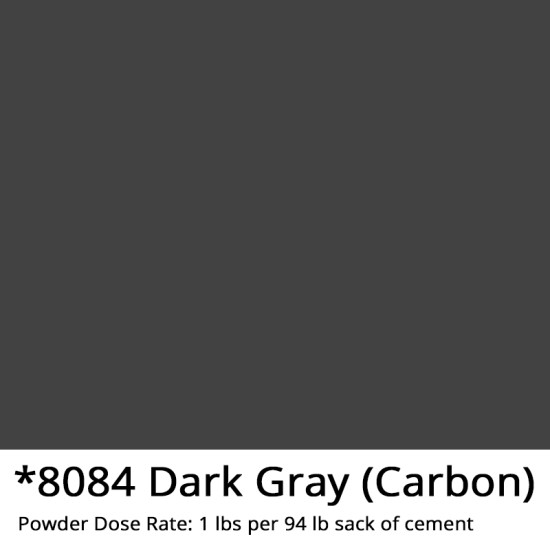

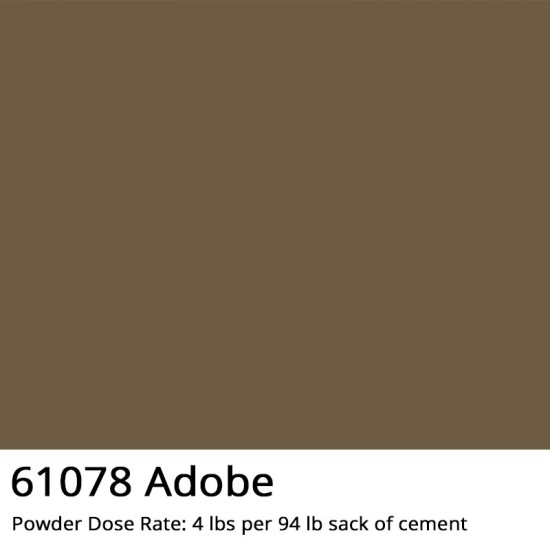

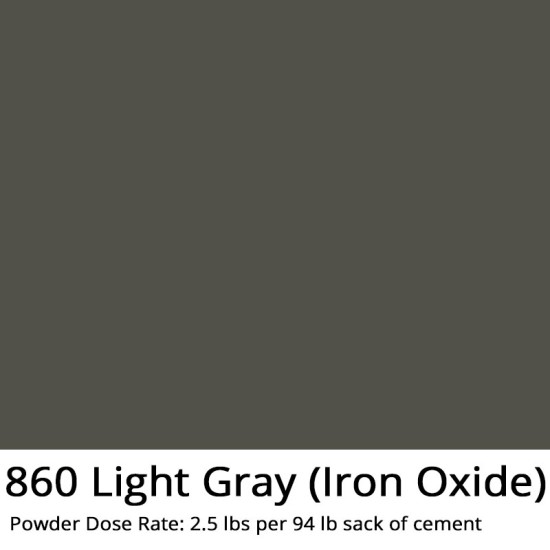

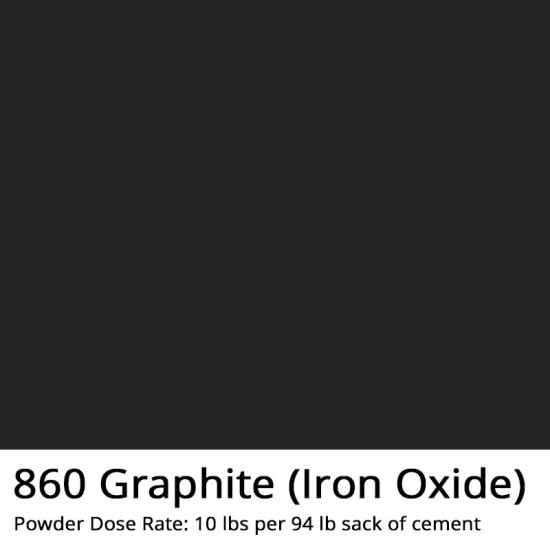

Concrete Oxide Pigment

Oxide Concrete Colors for Concrete. 1Lb-(0.45kg) Mix Ready bag.

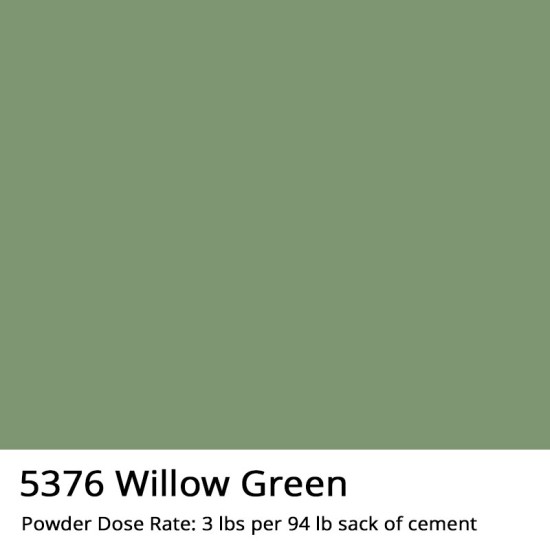

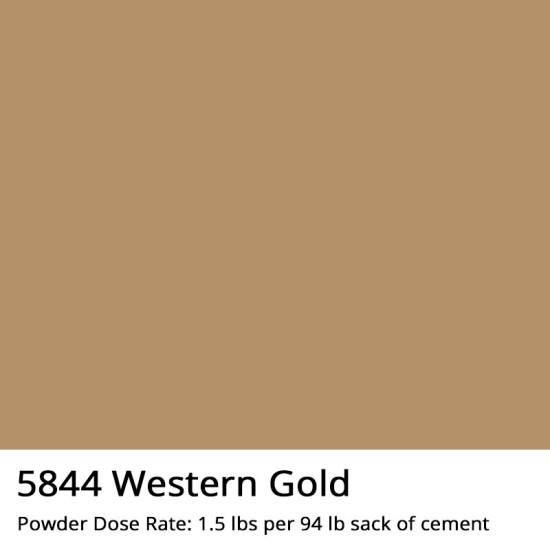

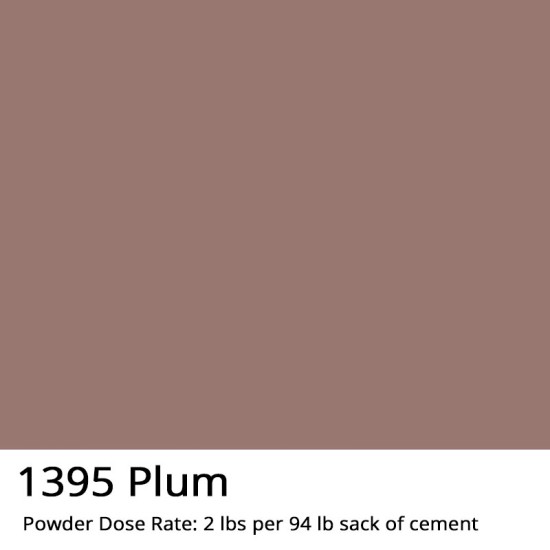

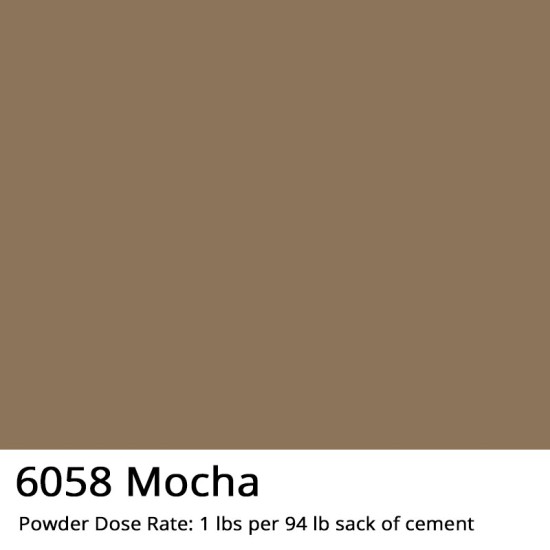

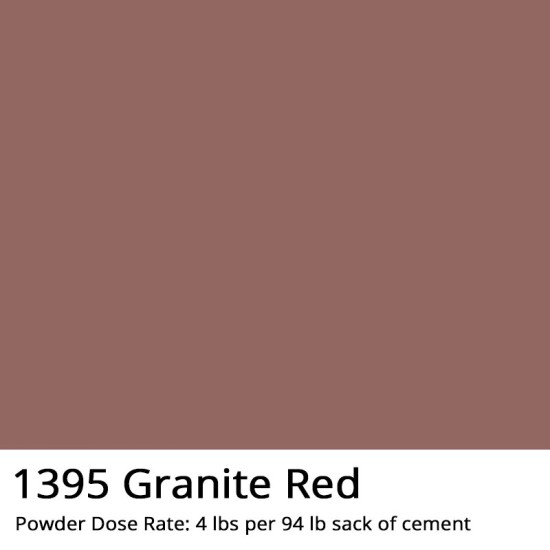

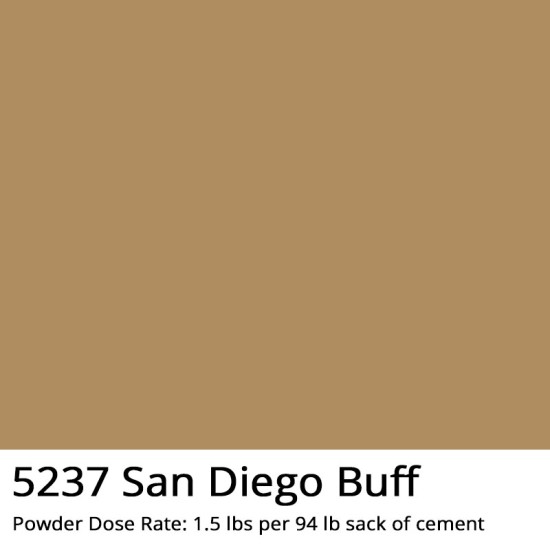

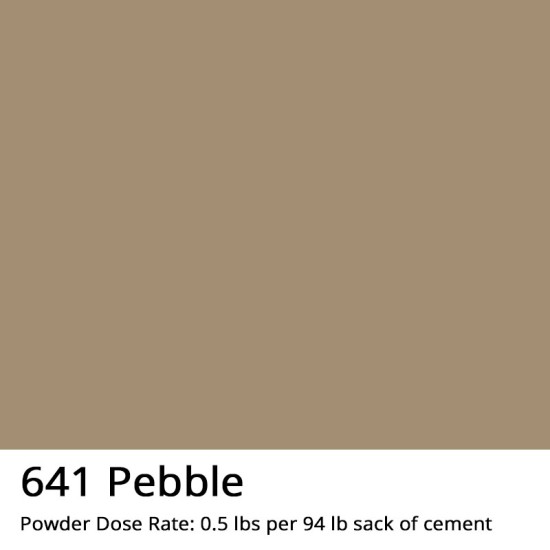

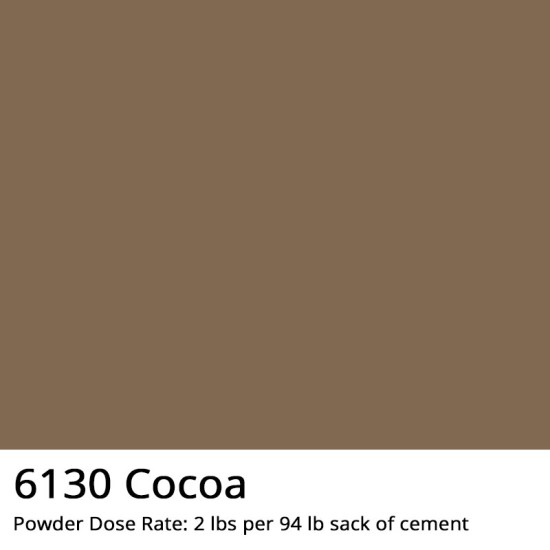

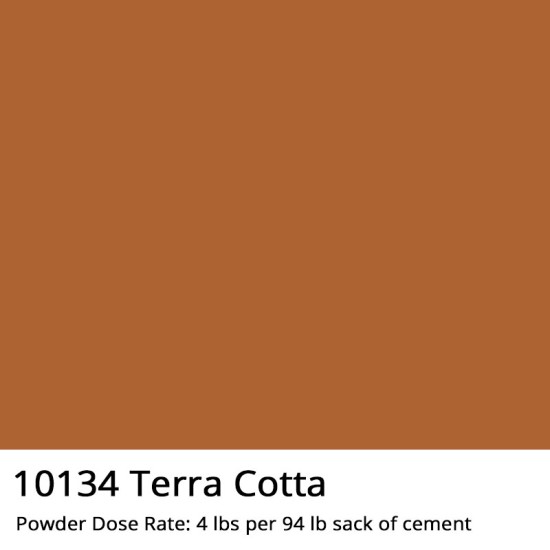

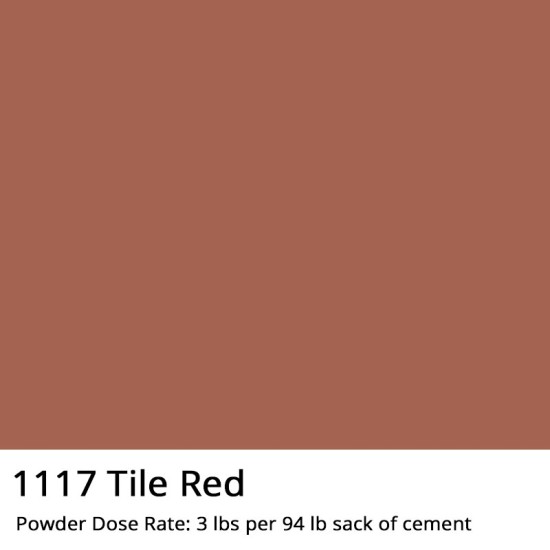

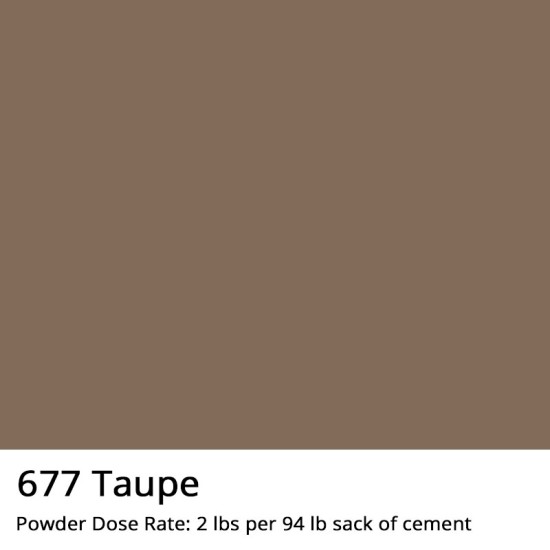

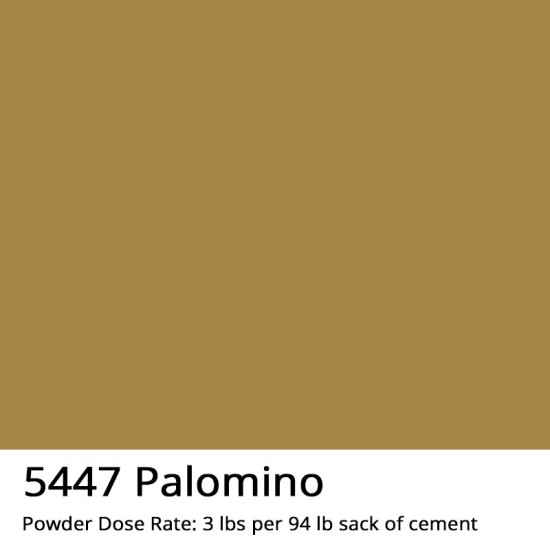

Photos of Concrete Tiles colors

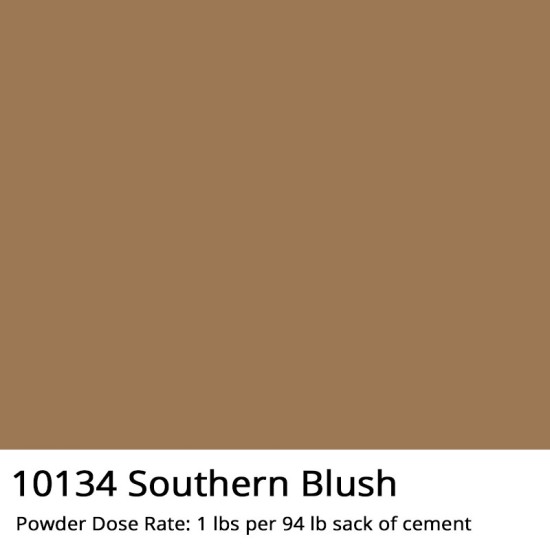

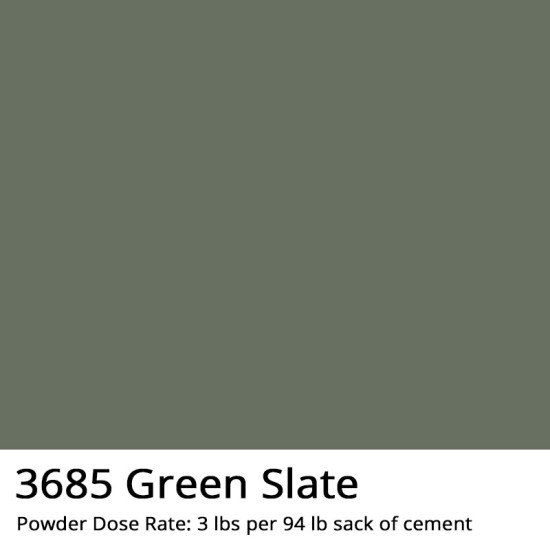

Select "Measuring" icon to preview concrete pigment dosage rate.

Concrete Oxide Pigments and Colors. Our concrete oxide pigment is a dry powder that can be used to add color to concrete, stucco, plaster, mortar, grout, countertop mix and other cement materials. It is also used in the ceramic industry. Mix the concrete oxide pigment into any concrete, transforming it into a new design feature for veneer stone, paving stone and concrete countertops projects or to enhance appearance around the home. Davis Colors are strong, durable and last as long as the concrete. There are bold and intense premium colors, standard colors that add less than a dollar per square foot, and subtle shades for any budget.

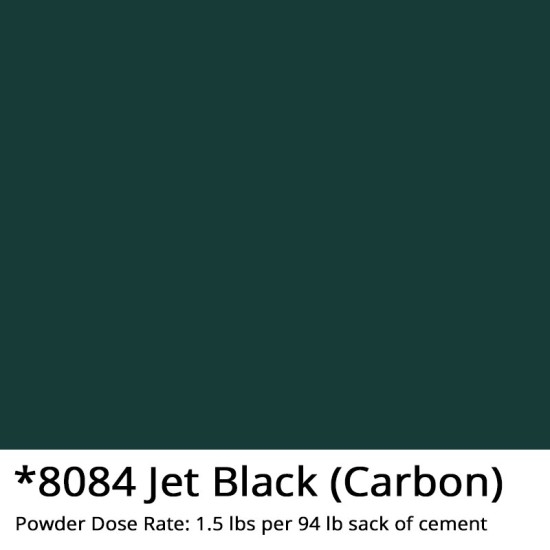

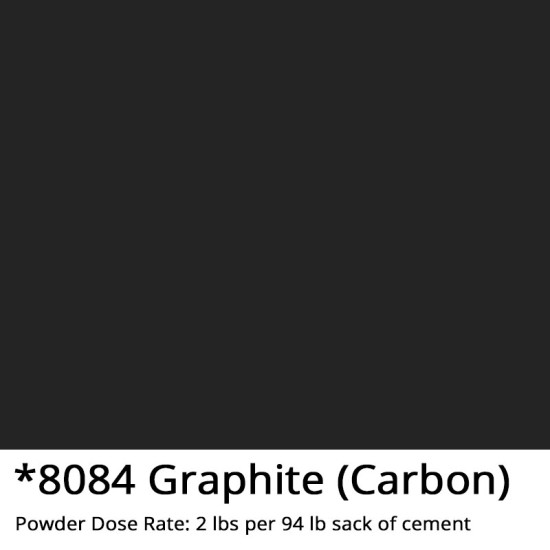

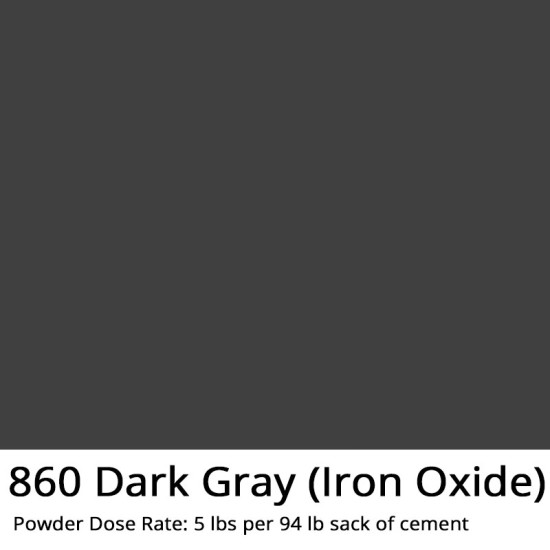

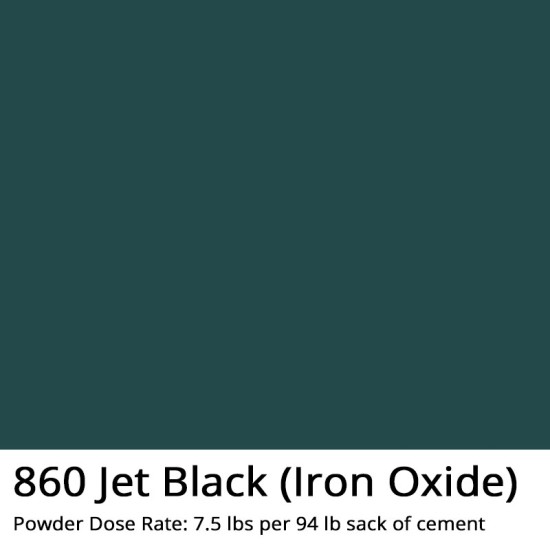

Each pigment can create a various concrete color options.

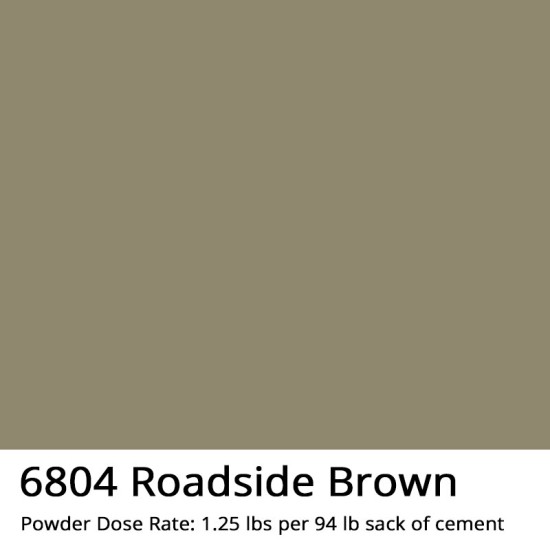

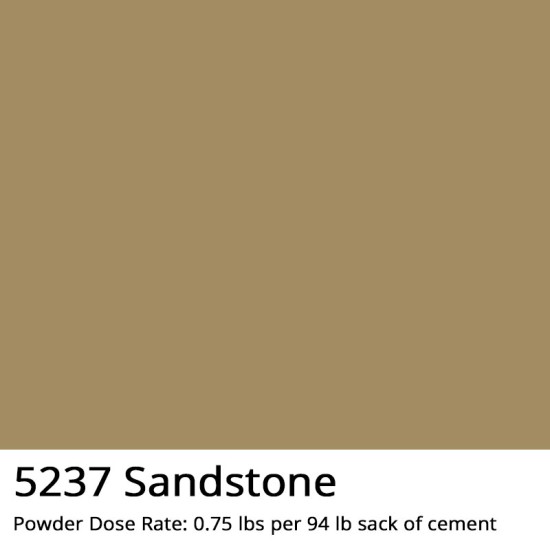

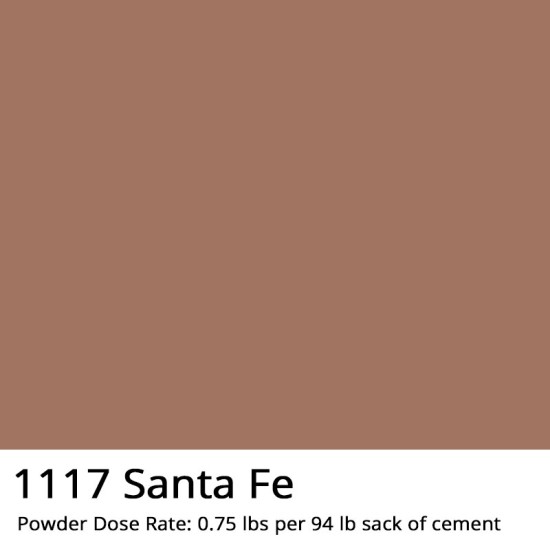

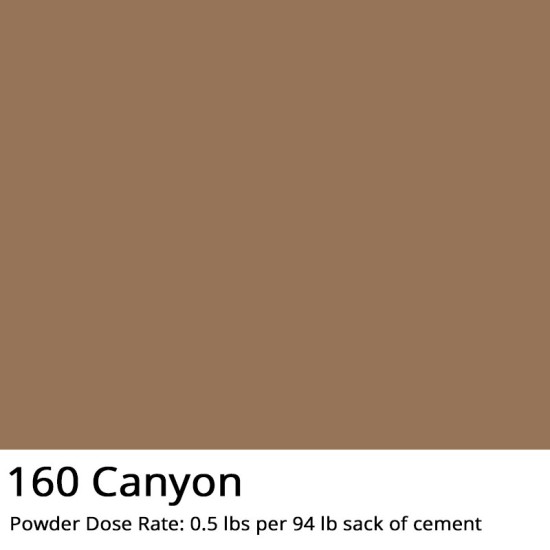

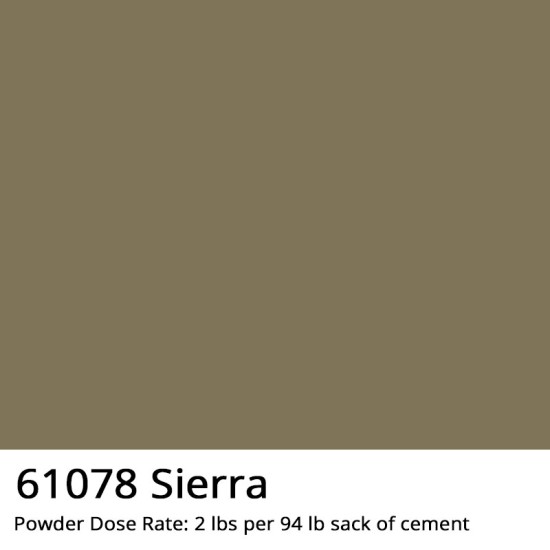

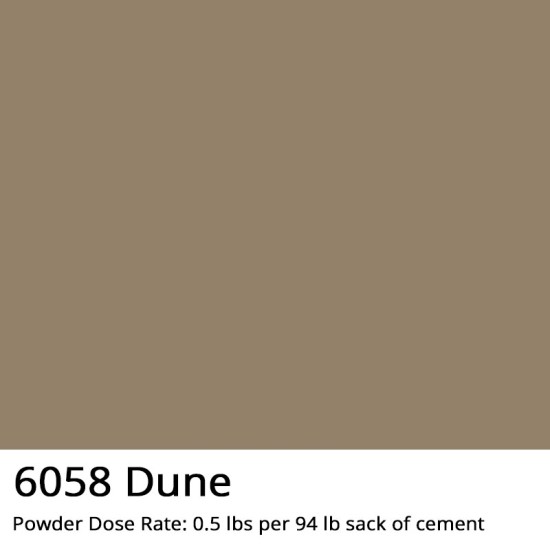

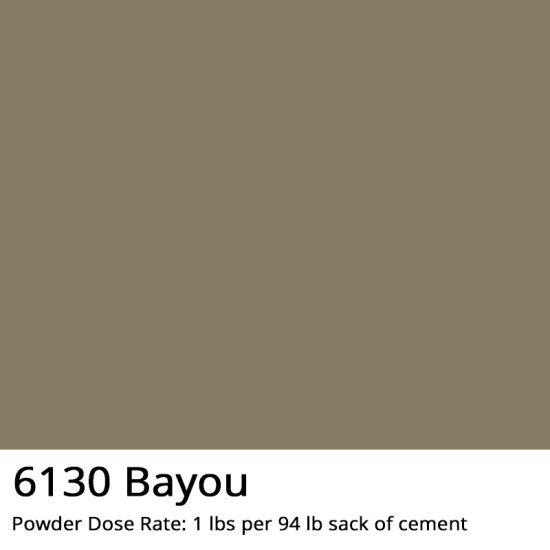

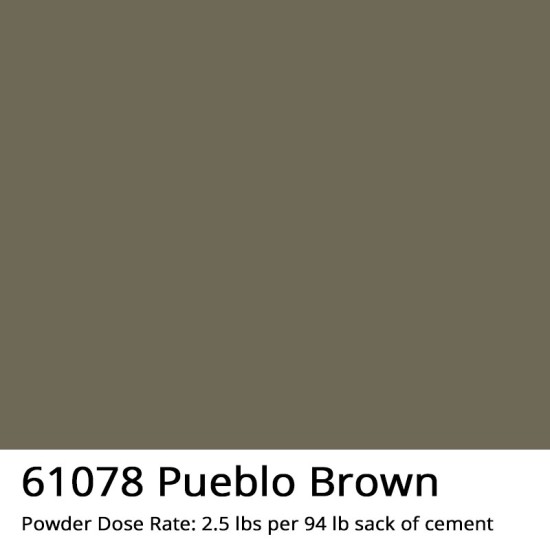

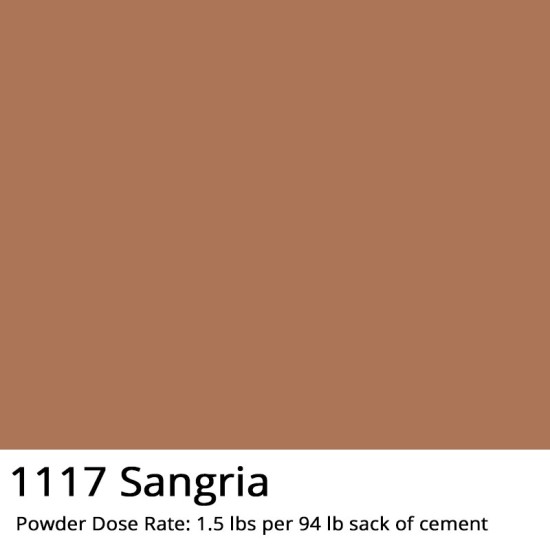

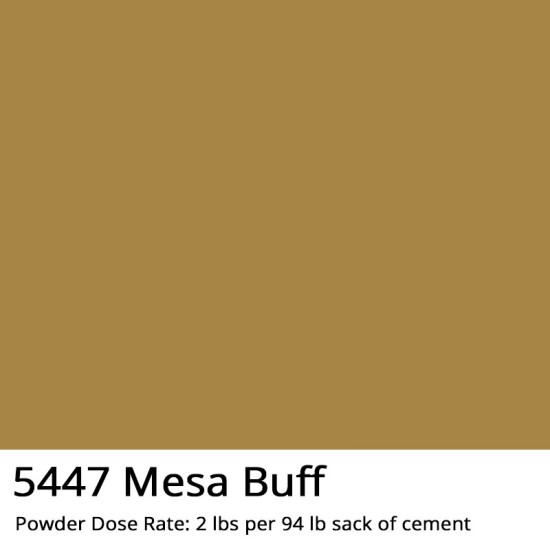

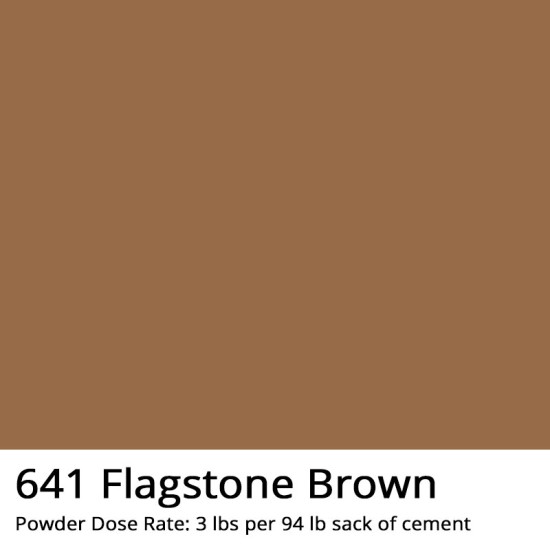

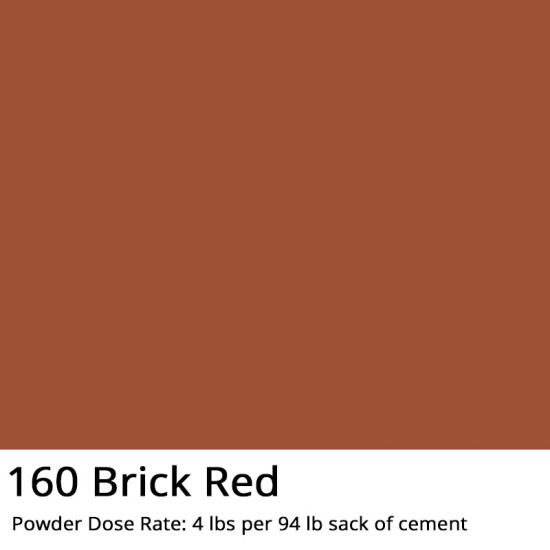

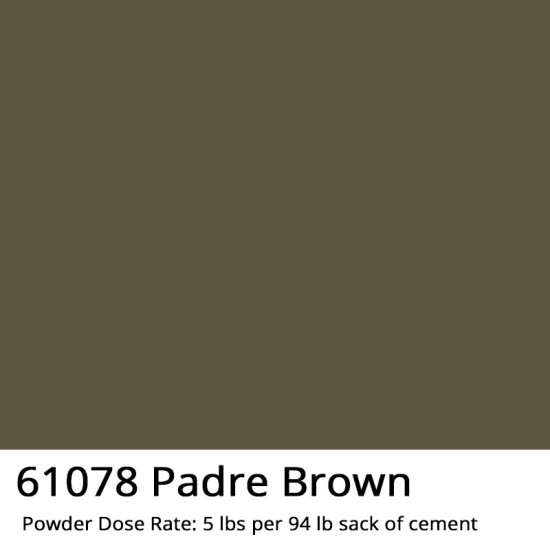

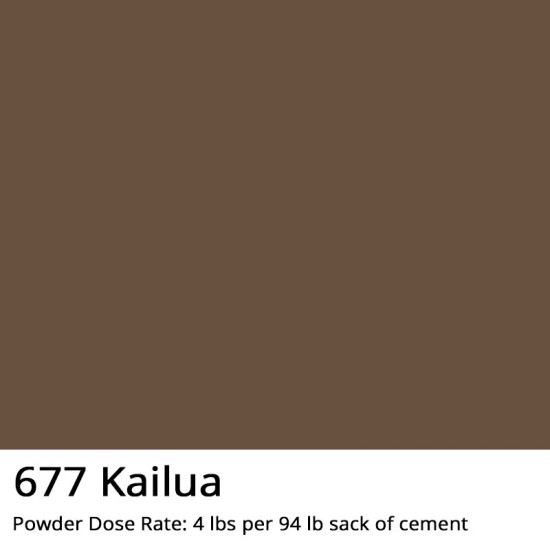

There is 20 based (standard colors). All of these colors can create different shades and intensities depending on the amount of powder used in the cast.

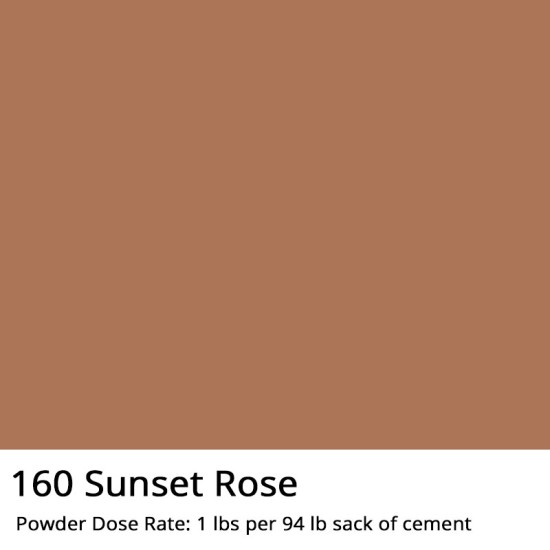

For example 160 color can create a 4 different color tones depends to pigment to cementitious material usage rate.

160 Canyon color - Powder Dose Rate: 0.5 lbs per 94 lb sack of cement

160 Sunset Rose color - Powder Dose Rate: 1 lbs per 94 lb sack of cement

160 Baja Red color - Powder Dose Rate: 2 lbs per 94 lb sack of cement

160 Brick Red color - Powder Dose Rate: 4 lbs per 94 lb sack of cement

Please note: pigment dosage calculated by cementitious material weight.

For more details, please refer to our pigment dosage chart

How much white pigment to use for concrete video link

MIX-READY INTEGRAL COLORS

Concrete oxide pigment loading rate is between 1% and 10% depending on depth of color required in the mix.

PLEASE BE ADVISED THAT COMPUTER SCREENS AND CAMERA SHOTS CAN GIVE VARIOUS COLORATION DIFFERENCES IN THE SAMPLE PICTURES. ADDITIONALLY CONCRETE CONTENT AND ENVIRONMENTAL FACTORS CAN DRASTICALLY CHANGE COLOR RESULTS.

This concrete oxide pigment is lightfast, odorless, alkali and weather resistant, UV stable, non-hazardous, chemically inert, water insoluble, providing consistent color.

Innovative Mix-Ready bags disintegrate during mixing for clean color handling and no environmental waste.

Mix-Ready is the original disintegrating bag for concrete colors and has been used successfully in millions of yards of concrete.

Mix-Ready bags end the dirty looks from drivers with dust in their faces, and from dispatchers upset that measuring and adding color the old-fashioned way delays trucks.

Toss in and mix. No opening required.

Ready Mix operators just toss unopened Mix-Ready bags into concrete mixer. Mix-Ready bags are made of special paper and adhesive which get soggy when wet and disintegrate during mixing. The bags release Mix Ready Concrete Color deep in the mixer to disperse uniformly. Color handling is clean and environmental waste is minimized.

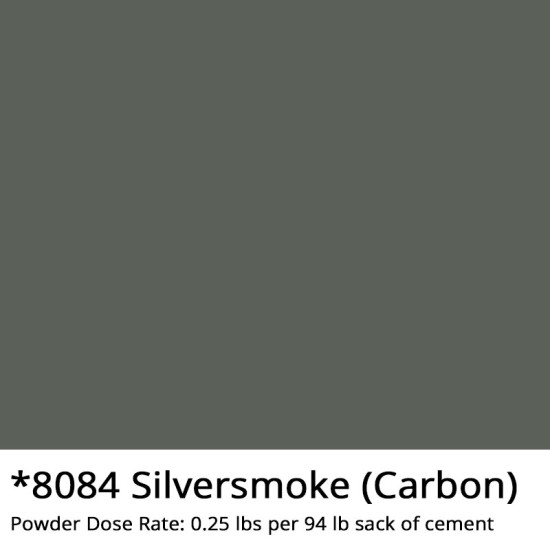

Mix Ready Concrete Colors are lightfast, lime-proof, weather-resistant color “admixtures” made of metal or mineral oxides either recycled from iron or refined from the earth. (Supra-Instant Black is a concentrated carbon black, treated in a proprietary process for extra tint strength and dispersibility. It is an economical alternative where concrete is not air-entrained and is protected against water damage.)

Mix Design

Determine pigment number and pigment dosage rate from our Color Card. Custom shades are made by varying the amount of color added to the mix. Typical dosage rates range from one to five pounds of Mix-Ready per 94 pound (1 cu. ft.) of cement content. Approx. 1 to 5% of cement content. Cement content includes portland cement, fly ash, silica fume, lime and other cementitious materials but not aggregate or sand.

INSTALLATION: Integrally colored concrete is installed the same way as high quality uncolored concrete. Choose a color on the inside of this color card and specify it by name and color number. Create a custom color by varying the amount of color added to the mix. Confirm desired color with a fully-cured job-site test panel. Dry color dose rates range from 1/2 to 7 lbs. per 94 lbs. of cement content and should never exceed 10% of cement content. (Liquid dose rates are higher). Cement content includes portland cement, fly ash, silica fume, lime and other cementitious materials but does not include aggregate or sand. Davis Colors have been used successfully in a wide variety of mix designs and are compatible with commercially available admixtures. The only known incompatibility is with calcium chloride set accelerator which causes blotching and discoloration. Supra-Instant black #8084 reduces or negates the effect of air-entraining admixtures.

If you need other colors that we don’t have listed you can contact us and we can order it. If you need larger amounts let us know and we’ll send you a quote.

Pigment available in 1 & 25 lbs. bags.

Frequently Asked Questions about Concrete Oxide Pigments

Q: How much pigment do I add per YARD of concrete?

A: This depends on the shade you want from each pigment. Our normal doses are based on 96 lb. sacks of cement. Most ready-mix plants add 6 sacks per yard of concrete. Therefore, all we need to do is multiply the original dosage rate by 6. Always check with the ready-mix plant to see if they add a different dosage rate, which will affect the final color.

(see attached color chart for dose rates per color name):

- 0.25 lb dose rate = (0.25 x 6 sacks) = 1.5 lbs of pigment per yard

- 0.50 lb dose rate = (0.50 x 6 sacks) = 3.0 lbs of pigment per yard

- 0.75 lb dose rate = (0.75 x 6 sacks) = 4.5 lbs of pigment per yard

- 1.0 lb dose rate = (1.0 x 6 sacks) = 6.0 lbs of pigment per yard

- 1.25 lb dose rate = (1.25 x 6 sacks) = 7.5 lbs of pigment per yard

- 1.5 lb dose rate = (1.5 x 6 sacks) = 9.0 lbs of pigment per yard

- 2.0 lb dose rate = (2.0 x 6 sacks) = 12.0 lbs of pigment per yard

- 3.0 lb dose rate = (3.0 x 6 sacks) = 18.0 lbs of pigment per yard

- 4.0 lb dose rate = (4.0 x 6 sacks) = 24.0 lbs of pigment per yard

- 5.0 lb dose rate = (5.0 x 6 sacks) = 30.0 lbs of pigment per yard

- 7.5 lb dose rate = (7.5 x 6 sacks) = 45.0 lbs of pigment per yard

- 10.0 lb dose rate = (10.0 x 6 sacks) = 60.0 lbs of pigment per yard

| File | Size | |

|---|---|---|

| 160-safety-data-sheet-sds.pdf | 122.41KB | Download |

| 160-technical-data-sheet-tds.pdf | 629.78KB | Download |

| 902-tds.pdf | 44.95KB | Download |

| 8084-tds.pdf | 29.79KB | Download |

| 10329-sds.pdf | 363.3KB | Download |

| 10329-tds.pdf | 28.8KB | Download |

| carbon-black-with-dispersant-8084-us-en.pdf | 325.87KB | Download |

| titanium-dioxide-902-us-en.pdf | 282.99KB | Download |