- Stock: In Stock

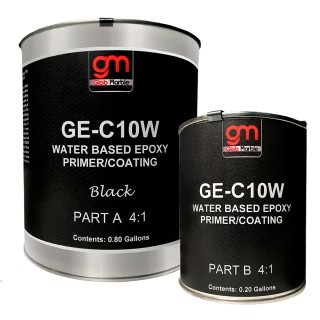

- Model: ColorTec 500

Available Options

Pigmented Epoxy Floor Coating 100% Solids From SureCrete (3-Gal Kit)

ColorTec 500 Pigmented Epoxy Floor Coating is a 2 component 100% solids, zero VOC epoxy floor coating system that is used in a wide variety of applications: as a high build color coat for a different decorative concrete systems, and as a primer coat and binder coat for Dura-Kote Flakes and Metallics. The high performance, self-leveling characteristics generate the premier balance of strength, flexibility, and chemical resistance that is both user-friendly and extremely durable.

Pigmented 100% epoxy floor coating may be utilized in a large variety of design applications, including, but not limited to the Except Dura-Kote Epoxy Flakes and Dura-Kote Epoxy Metallics systems. Pigmented 100% epoxy floor coating may be utilized in application of more creative, three-dimensional coatings.

ColorTec 500 Pigmented Epoxy Floor Coating is ideally suited for any commercial or residential setting: manufacturing facilities, warehouses, bars, clubs, retail stores, automotive showrooms, residential interiors, garage floors, gyms, locker rooms, stadiums, living area applications, commercial flooring applications, or anywhere that an exceedingly resilient floor is desired.

*Please note that all ColorTec products are mixed to order and are non-returnable and non-refundable.*

Packaging:

3 gal. (11.4 l) kit:

1-3 gal. (11.4 l) short filled pail containing 2 gal. (7.6 l) part A (pigmented), 1-1 gal. (3.8 l) pail part B

Mixing Ratio: 2:1 (2 part A to 1 part B)

Pigmented Epoxy Floor Coating Coverage:

As color coat: approximately 100 – 150 ft2 per gal. (9.3–13.9 m2 per 3.8 l) 10.7–16 mils

For thick build: 40 – 70 ft2 per gal. (3.7–6.5 m2 per 3.8 l) 23-40 mils

Dura-Kote Epoxy Metallics OR Dura-Kote Epoxy Flakes systems

Primer Coat: Dura-Kote Pigmented Epoxy 100

Top Coat: Dura-Kote Metallics to Dura-Kote Epoxy 100 (120-210 ft2 for 3 gallons).

Finish Coat: Dura-Kote PFC 120

Optional: Sure Grip (Non Slip Sealer Additive HD)

Spiked shoes are required throughout application

Appropriate Rollers: Roller cover with nap size from mohair to 3/8", phenolic core, "De-fuzz", for large areas may require 18" rollers and wider squeegees – you may choose WOOSTER RR642 18" PRO DOO-Z 3/8" NAP ROLLER COVER.

How To Use:

- Any surface that is about to be sealed must be completely cured, clean and free of any contaminates. Also make sure that it is fully profiled and etched.

- Make sure that the temperature will stay between 50-90 degrees Fahrenheit, and that you will have a relative humidity below 75%. Be sure that there will be no type of precipitation for the next 12 hours.

- Pour 1 part B and 2 part A into a clean mixing container and mix mechanically for at least 3 minutes

- Use a premium de-fuzzed, phenolic core roller like EpoxyGlide. Roll thin coats onto the desired surface for a thin coating. OR use a notched squeegee for a thicker coating and to fill small holes.

- Backroll with a roller to remove any roller marks.

- The first coating can be used alone, but if a much more scratch resistant surface is desired, you may apply a polyaspartic sealer. You will need to sand the first coat with 100 grit, and remove all the dust and debris before applying the sealer.

- Optional: Use a sacrificial wax like SureFinish to prolong the life of your floor, and to add slip resistance.

Where To Use: Man-Cave Floor Designs, Retail Flooring, Living Area Applications, Commercial Flooring, Vibrant-Color Sealers, University and School Colored Flooring, Sports Team Floor Theming, Sports Arena Floor Paint, Stadium Colored Coatings.

Frequently Asked Questions About ColorTec 500

Q: Can Dura-Kote Colored Epoxy 100 be used as a single-coat system?

A: It definitely can, but we usually suggest a finish coat be applied as well as a sacrificial coating for better scratch and chemical resistance and to ensure the overall system lasts as long as possible.

Q: Will Colored Concrete Floor Epoxy 100 self-level and fill small holes?

A: For small holes, yes (If you apply it thick enough). Filling large holes isn’t recommended because if the epoxy is too thick, it can degrade the surface stability and longevity.