- Stock: In Stock

- Model: WB-PIGMENTED-SEALER

Available Options

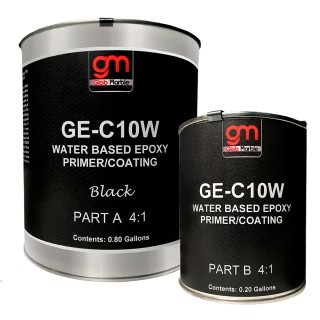

Water-Based Clear Epoxy Coat 2-Gal kit, Primer and Sealer for Interior Concrete

DK 600WB is a two-component, 85% solids floor coating for interior concrete and cement- based overlays. The high performance clear top coat, provides the durability of a solvent base system with the ease and safety of a 0 VOC water base system that is both user-friendly and extremely durable.

DK 600WB is also used as a primer and/or bond coat for specific SureCrete concrete topping applications and has remarkable properties related to moisture:

- Withstands high vapor transmission rate, up to 13 pounds per 1,000 ft² (5.4 kg per 100m²) in 24 hours.

- Provides a non-permeable vapor barrier, even in basements.

- Applies on fresh concrete as soon as three days after pouring and placing concrete.

DK 600WB is ideally suited for both commercial and residential settings: manufacturing facilities, warehouses, bars, clubs, retail stores, automotive showrooms, hospitals, medical centers, residential interiors, garage floors, gyms, locker rooms, stadiums, or anywhere that an exceedingly resilient floor is desired.

Coverage: 125-175 sqft per gallon catalyzed product (varies widely based on application method). For smooth surface or second coat approximately 200 - 250 ft² per gal.

*Please note that all ColorTec products are mixed to order and are non-returnable and non-refundable.*

How To Use:

- Any surface that is about to be sealed must be completely cured, clean and free of any contaminates. Also make sure that it is fully profiled and etched.

- Make sure that the temperature will stay between 50-90 degrees Fahrenheit, and that you will have a relative humidity below 75%. Be sure that there will be no type of precipitation for the next 12 hours.

- Pour 1 part A and 1 part B into a clean mixing container and mix mechanically for at least 3 minutes

- Use a premium de-fuzzed, phenolic core roller like EpoxyGlide. Roll thin coats onto the desired surface

- Backroll with a roller to remove any roller marks

- Two layers are suggested with any interior project. Make sure your first coating is dry to the touch (within 6-8 hours) and apply your second coat. If it has been allowed to cure for over 12 hours, sand the surface with 100 grit and remove the dust and debris. You can then roll on your second coat.

- Optional- Use a sacrificial wax like SureFinish to prolong the life of your floor, and to add slip resistance.

Please leave a review

Write Review