- Stock: In Stock

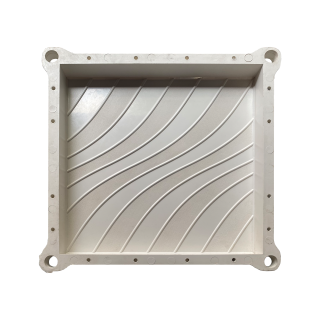

- Model: WS 5002

Available Options

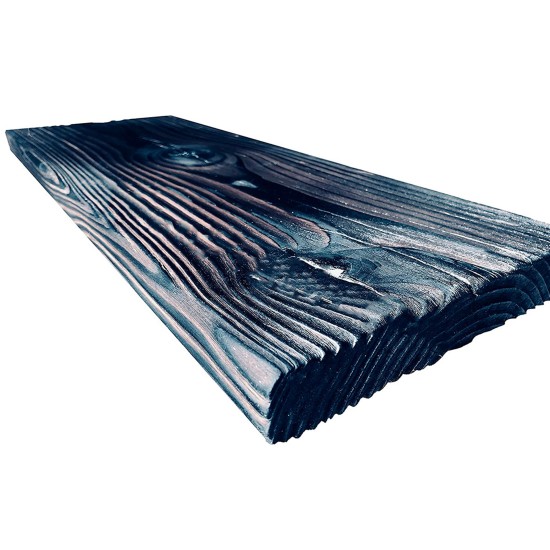

Create hyper-realistic wood plank texture in concrete with the WS 5002 series. Each two-section mold captures crisp grain, knots, and texture on casting face and walls so your concrete stepping stones look like real wood—without rot, splinters, or seasonal movement. Use oxide pigments for integral color, water-based stains for topical toning, and a compatible sealer to build layered, natural wood tones for patios, walkways, and garden paths.

Mold variations /1 /2 /3 /4 /5 /6 are of the same wood type but made from different individual planks. Mixing mold variations across a project prevents repetition and guarantees a natural, non-uniform look.

Tech specs

WS 5002 /1, /2, /3

All mold variations produce planks 9" in width, and 1.5" in thickness

Mold variations /1,/2,/3 produce planks 25.5" in length

Approx. mold size: 27.5" x 20.5" x 2" (70 cm x 52 cm x 5 cm)

Output: 2 planks per casting

Approx. plank size: 25.5" x 9" x 1.5" (65 cm x 23 cm x 3.5 cm)

Please check the combination of the Wood Plank Concrete mold WS 5002 /1, /2, /3 with Wood Logs Concrete Mold WS 5902 for your new concrete wood floor design idea.

WS 5002 /4, /5, /6

All mold variations produce planks 9" in width, and 1.5" in thickness

Mold variations /4,/5,/6 produce planks 34.5" in length

Approx. mold size: 36.25" x 20" x 2" (92 cm x 50 cm x 5 cm)

Output: 2 planks per casting

Approx. plank size: 34.5" x 9" x 1.5" (87 cm x 23 cm x 3.5 cm)

Recommended products

Oxide pigment: Mixed directly into concrete to color it integrally. Commonly used as a "base color" of concrete castings

Water-based stain: Topical, semi-translucent stain which adds secondary color to enhance realism.

G1 Mold Release: Used on the mold to prevent concrete stciking to the rubber. Can also be used to clean dirty molds

Sealer (exterior):

GA-20 — solvent-based acrylic (gloss)

GA-25 — water-based acrylic (gloss)

SC Matting Agent — solvent-acrylic matte additive (use with GA-20)

Sealer (interior):

GU-20 — solvent-based polyurethane (gloss or satin)

GU-20WB — water-based polyurethane (gloss or flat)

WS 5002/1, 5002/2, 5002/3 Stone-casting Instructions:

Always apply release agent to your mold prior to casting concrete.

WS 5002/1, 5002/2, 5002/3 mold casting weight is about 39.73 lbs (18.04 kg).

We use this 1:2 cement to filler ratio mix: (you can also mix 1-part Portland cement to 3 parts sand (filler), but plasticizer and water has to be re-calculated by cement weight).

- 13.24 lbs (6.01 kg) Portland cement (white for light stone colors, gray for dark stone colors)

- 26.48 lbs (12.03 kg) Sand (20-30 mesh recommended. Silica sand or "all-purpose" sand works great)

- 52.97 oz (1.44 L) Water (We recommend water to be 20%-30% of cement weight). If your mix is too liquid, use less water

- 2.12 oz (60.13 g) super-plasticizer (Superplasticizer's dosage rate is 0.5% - 1% of cement weight. We are using 1%)

For best result always add dry pigments to your mix prior to adding the water. Mix concrete with pigment and additives for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting, then mix with dry ingredients.

Please note: Concrete minimum mixing time is 3 minutes (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction).

To color different molds sections, brush oxide pigment over the selected sections, then cast the concrete.

Cover the mold with plastic while it is curing. Remove the stone from the mold in 12-24 hours.

WS 5002/4, 5002/5, 5002/6 Stone-casting Instructions:

Always apply release agent to your mold prior to casting concrete.

WS 5002/4, 5002/5, 5002/6 mold casting weight is about 53.75 lbs (24.41 kg).

We use this 1:2 cement to filler ratio mix: (you can also mix 1-part Portland cement to 3 parts sand (filler), but plasticizer and water has to be re-calculated by cement weight).

- 17.92 lbs (8.14 kg) Portland cement (white for light stone colors, gray for dark stone colors)

- 35.83 lbs (16.27 kg) Sand (20-30 mesh recommended. Silica sand or "all-purpose" sand works great)

- 71.66 oz (1.95 L) Water (We recommend water to be 20%-30% of cement weight). If your mix is too liquid, use less water

- 2.87 oz (81.35 g) super-plasticizer (Superplasticizer's dosage rate is 0.5% - 1% of cement weight. We are using 1%)

For best result always add dry pigments to your mix prior to adding the water. Mix concrete with pigment and additives for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting, then mix with dry ingredients.

Please note: Concrete minimum mixing time is 3 minutes (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction).

To color different molds sections, brush oxide pigment over the selected sections, then cast the concrete.

Cover the mold with plastic while it is curing. Remove the stone from the mold in 12-24 hours.

Frequently Asked Questions

Q: What’s the difference between /1, /2, /3, /4, /5, /6?

A: All six are the same wood type, but each model has a unique plank texture. Use multiple models together to prevent repeating patterns.

Q: Which sizes do the codes belong to?

A: WS 5002/1, /2, /3 share one size; WS 5002/4, /5, /6 share a larger size. See Tech Specs above for dimensions.

Q: How do I achieve a realistic wood look from concrete?

A: Add Oxide pigment integrally for a base tone, then apply water-based stain after cure to accent grain and knots. Finish with the sealer that fits your sheen, traffic, and UV needs.

Q: Which sealer should I choose?

A: Exterior: Acrylic sealers (solvent based GA-20 or water based GA-25). Interior: polyurethane sealers (Solvent based GU-20 or based GU-20WB).

Q: Do I need a release agent?

A: Yes, apply G1 Mold Release in a fine mist before pouring the concrete to prevent concrete from sticking and to reduce surface bubbles.