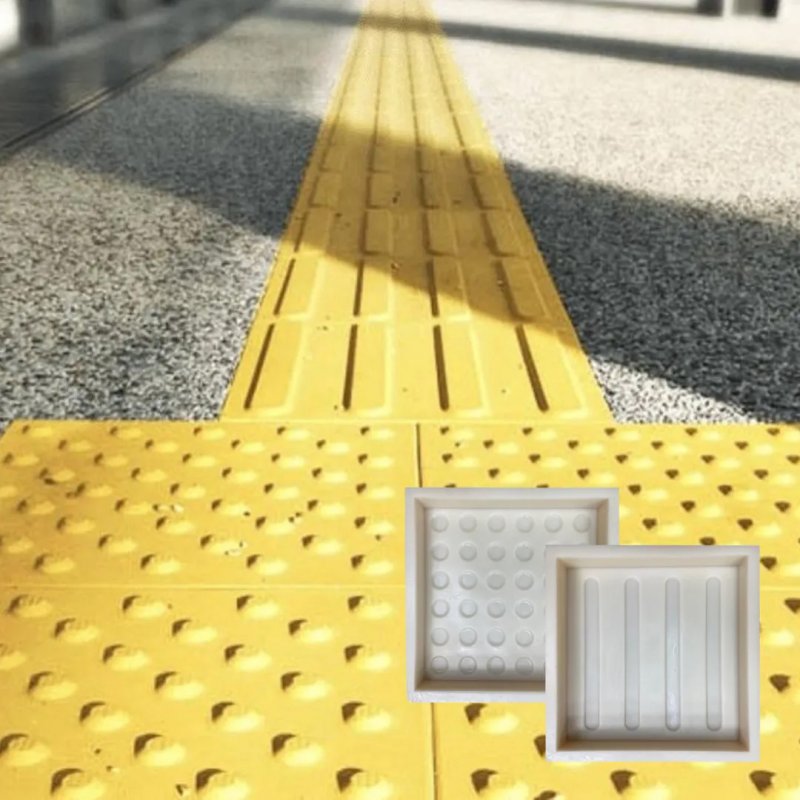

ADA-Compliant Tactile Warning Surface Tile Mold PS 60100

Enhance safety and accessibility in public spaces with the ADA-Complained Tactile Warning Surface Mold PS 60100 Series. These high-quality polyurethane molds are designed to create durable ADA detectable warning surfaces, ensuring compliance with safety regulations and providing essential guidance for visually impaired pedestrians.

PS 60100/1, PS 60100/2 molds dimensions

Approximate mold dimensions: 13 1/4" x 13 1/4" (33.50 cm x 33.50 cm).

Approximate tactile warning surface dimensions: 11 1/2" x 11 1/2" x 2" (29.50 cm x 29.50 cm x 5 cm).

PS 60100/3 mold's dimensions

Approximate mold dimensions: 38 3/4" x 26 1/4" x 2 3/4" (98 cm x 66 cm x 7 cm).

Approximate tactile warning surface dimensions: 36 1/2" x 24 " x 2" (93 cm x 61 cm x 5 cm).

Key Features of Tactile Warning Surface Mold PS 60100

- Durable Polyurethane Construction: Made from high-quality polyurethane, these molds withstand repeated use and ensure precise, consistent results.

- ADA Compliant Design: The molds produce tactile warning tiles that meet ADA standards, enhancing accessibility and safety.

- Flexible Sizing Options: Choose from multiple mold sizes to accommodate different project requirements, including sidewalks, train platforms, and ramps.

- Simple Casting Process: With detailed instructions, you can create detectable warning tiles efficiently, even for large-scale projects.

- Cost-Effective Solution: Reduce project costs by producing your own tactile surfaces with customizable colors.

Why Choose ADA Detectable Warning Surfaces?

ADA detectable warning surfaces are essential for public safety, providing tactile and visual cues that signal changes in walking paths, such as street crossings or platform edges. These tactile warning tiles help prevent accidents and ensure inclusivity for all pedestrians.

Step-by-Step Guide to Casting Tactile Warning Tiles

PS 60100 mold casting weight is about 15.26 lb (6.93 Kg)

We use this 1:2 cement to filler ratio mix: (you can also mix 1-part Portland cement to 3 parts sand [filler], but plasticizer and water has to be re-calculated by cement weight).

- 5.09 lbs (2.31 kg) Portland cement (white for light stone colors, gray for dark stone colors);

- 10.17 lbs (4.62 kg) Sand (20-30 mesh recommended. Silica sand or "all-purpose" sand works great);

- 20.35 oz (0.55 L) Water (We recommend water to be 20%-30% of cement weight). If your mix is too liquid, use less water;

- 0.81 oz (23.1 g) Super-plasticizer (Superplasticizer's dosage rate is 0.5%-1% of cement weight. We are using 1%).

For best result always add dry pigments to your mix prior to adding the water. Mix concrete with pigment and additives for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting, then mix with dry ingredients.

Please note: Concrete minimum mixing time is 3 minutes (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction).

To color different molds sections, brush oxide pigment over the selected sections, then cast the concrete.

Cover the mold with plastic while it is curing. Remove the stone from the mold in 12-24 hours.

Applications of Tactile Warning Surface Molds

These molds are ideal for creating:

- Sidewalk Safety Zones: Install tactile tiles to signal street crossings.

- Train and Bus Platforms: Enhance safety by defining platform edges.

- Commercial Walkways: Provide ADA-compliant surfaces in shopping centers and public buildings.

- Ramps and Entrances: Ensure safe navigation for individuals with visual impairments.

Enhance Public Safety with Tactile Warning Tiles

Invest in the Tactile Warning Surface Mold PS 60100 Series to create durable and compliant ADA detectable warning surfaces. Whether you're working on public infrastructure or private projects, these molds offer a reliable, cost-effective solution for improving accessibility and safety.

Order your Tactile Warning Surface Mold PS 60100 today and create ADA-compliant tactile warning surfaces with ease. Enhance public safety and accessibility in your projects.