- Stock: In Stock

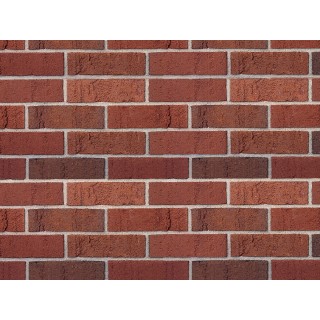

- Model: BS 711

Available Options

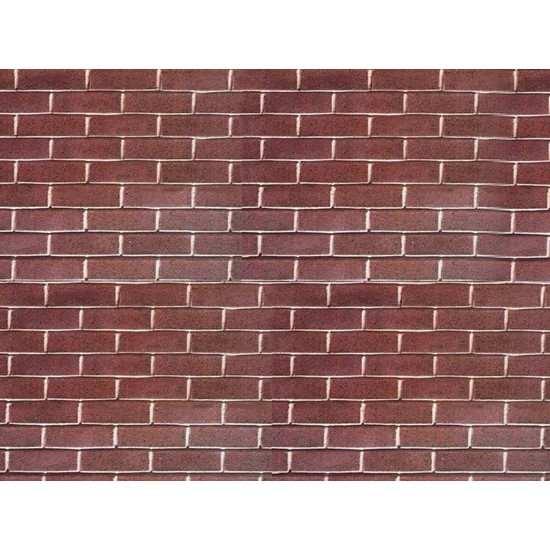

Brick Stone Mold BS 711/1

Mold size - 3 SQ.FT (0.28 m2) approximate.

Measurements - 24" x 16 1/2" x 1" (61 cm x 42 cm x 2.5 cm)

Mold sections - 18

Section dimensions: Approx. size of each section 7.5" x 2.25" x 0.5" (19 cm x 6 cm x 1.5 cm).

To have a wider stone pattern variety we recommend buying the following molds together.

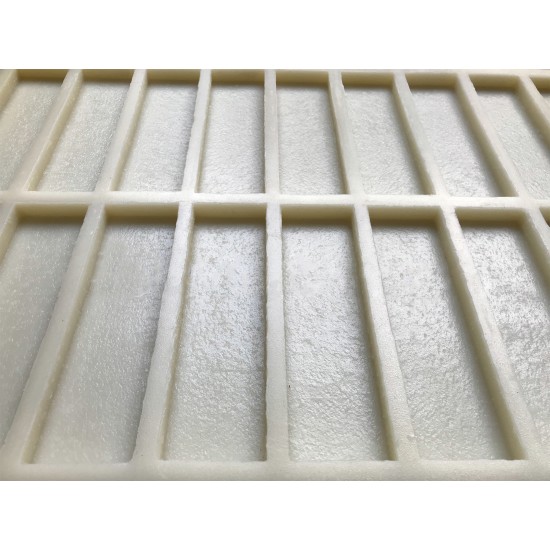

Brick Stone Mold BS 711/2 Corner

Mold size - 1.93SQ.FT (0.18 m2) approximate.

Measurements - 21 1/2" x 8 1/2" x 4 1/2" (54.5 cm x 21.5 cm x 11.5 cm)

Mold sections - 8

Section dimensions: Approx. size of each section 7.5" x 2.25" x 0.5" (19 cm x 6 cm x 1.5 cm).

How to cast GlobMarble brick stone mold instruction

How to Cast Corner Molds Instruction

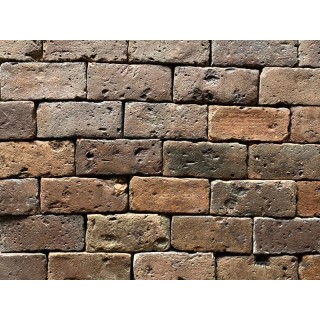

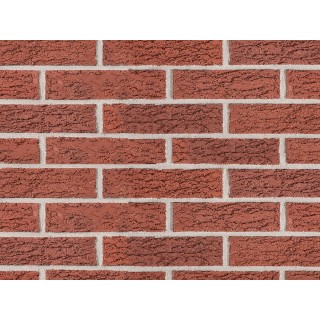

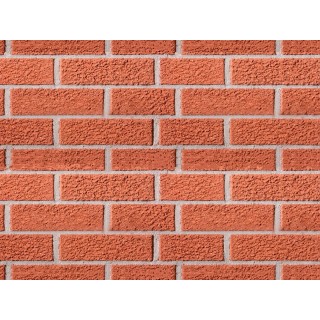

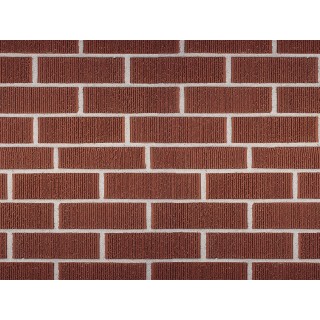

Concrete Stone Veneer Mold for Stone Bricks and Pavers

BS 711/1 Stone-casting Instructions:

Always apply release agent to your mold prior to casting concrete.

BS 711/1 mold casting weight is about 12.70 lbs (5.77 kg).

We use this 1:2 cement to filler ratio mix: (you can also mix 1-part Portland cement to 3 parts sand (filler), but plasticizer and water has to be re-calculated by cement weight).

- 4.23 lbs (1.92 kg) Portland cement (white for light stone colors, gray for dark stone colors)

- 8.46 lbs (3.84 kg) Sand (20-30 mesh recommended. Silica sand or "all-purpose" sand works great)

- 16.93 oz (0.46 l) Water. We recommend water to be 20%-30% of cement weight. If your mix is too liquid, use less water

- 0.68 oz (19.22 g) super-plasticizer (Superplasticizer's dosage rate is 0.5%-1% of cement weight. We are using 1%)

For best result always add dry pigments to your mix prior to adding the water. Mix concrete with pigment and additives for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting, then mix with dry ingredients.

Please note: Concrete minimum mixing time is 3 minutes (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction).

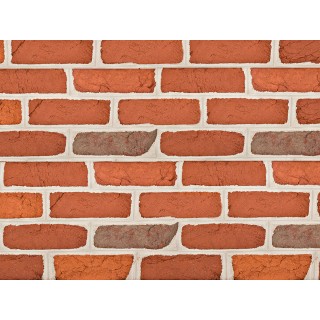

To color different molds sections, brush oxide pigment over the selected sections, then cast the concrete.

Cover the mold with plastic while it is curing. Remove the stone from the mold in 12-24 hours.

BS 711/2 Stone-casting Instructions:

Always apply release agent to your mold prior to casting concrete.

BS 711/2 mold casting weight is about 7.90 lbs (3.59 kg).

We use this 1:2 cement to filler ratio mix: (you can also mix 1-part Portland cement to 3 parts sand [filler], but plasticizer and water has to be re-calculated by cement weight).

- 2.63 lbs (1.20 kg) Portland cement (white for light stone colors, gray for dark stone colors)

- 5.27 lbs (2.39 kg) Sand (20-30 mesh recommended. Silica sand or "all-purpose" sand works great)

- 10.54 oz (0.29 l) Water. We recommend water to be 20%-30% of cement weight. If your mix is too liquid, use less water

- 0.42 oz (11.97 g) super-plasticizer (Superplasticizer's dosage rate is 0.5% -1% of cement weight. We are using 1%)

For best result always add dry pigments to your mix prior to adding the water. Mix concrete with pigment and additives for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting, then mix with dry ingredients.

Please note: Concrete minimum mixing time is 3 minutes (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction).

To color different molds sections, brush oxide pigment over the selected sections, then cast the concrete.

Cover the mold with plastic while it is curing. Remove the stone from the mold in 12-24 hours.

Frequently Asked Questions about Concrete Stamp Mats

Q: What is the difference between BS 711/1, 711/2 etc?

A: It the same family molds. Each mold has its own set of unrepeated to previous mold stone pattern. We’re recommend to cast several molds for wider variety stone pattern on surface.