- Stock: In Stock

- Model: PS 30085

Available Options

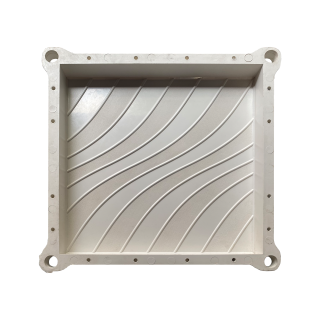

PAVER STONE MOLDS

Application areas for slip resistant paving stones include residential terrace, schools, traffic and pedestrian walkways, industrial and commercial buildings, landscape for open and closed court yards, and above all else, pool decks. Paver stones and tiles can be manufactured by anyone, including DIYers.

- PS 30085/1 - Textured finish with similar to 20 grit sandpaper texture for slip resistant pavers

- PS 30085/2 smooth finish decorative pavers

PS 30085 Paver size- 12” X 12” X 3”

PS 30085 Stone-casting Instructions:

Always apply release agent to your mold prior to casting concrete.

PS-30085 molds casting weight is about 24.9 lbs. (11.3 kg.)

We use this 1:2 cement to filler ratio mix : (you can also mix 1-part Portland cement to 3 parts sand [filler], but plasticizer and water has to be re-calculated by cement weight)

8.3 lbs (3.8 kg) Portland cement (white for light stone colors, gray for dark stone colors)

16.6 lbs (7.5 kg) Sand (20-30 mesh recommended. Silica sand or "all-purpose" sand works great)

33.2 oz (0.91 L) Water (We recommend water to be 20%-30% of cement weight.) (If your mix is too liquid, use less water.)

1.33 oz (37.7 g) Super-plasticizer (Superplasticizer's dosage rate is 0.5% -1% of cement weight. We are using 1%)

For best result always add dry pigments to your mix prior to adding the water. Mix concrete with pigment and additives for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting, then mix with dry ingredients.

Please note: Concrete minimum mixing time is 3 minutes (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction)

To color different molds sections, brush oxide pigment over the selected sections, then cast the concrete.

Cover the mold with plastic while it is curing. Remove the stone from the mold in 12-24 hours

Please leave a review

Write Review