- Stock: In Stock

- Model: Integral

Available Options

Integral Color - Fresh Concrete Color Powder

Ready Mix Concrete Pigments - 10-pound concrete colors bags provide the contractor with a light, fast, weather resistant, lime-proof, no maintenance finished product.

SureCrete Design Products maintain the highest tinting qualities with strength and color material consistency from bag to bag.

Color is conveniently packaged in a disintegrating bag that disperses safely and rapidly into the cement concrete batch, making it better than most ready-mix color companies in the market today.

Coverage

Avoid a sign discolorations concrete by sealing your concrete with a high-quality sealer.

Light: 0.5 Bag Color / 1 Yard.

Concrete Medium: 1 Bag Color / 1 Yard.

Concrete Dark: 2 Bags Color / 1 Yard Concrete.

Packaging: 1-10 lb Bag.

Description

Integral concrete colors are pure, synthetic, iron oxide pigments containing no fillers that will affect the performance of the concrete mix design. SureCrete Design Products concrete colors applications provide the user with a lightfast, weather resistant, lime-proof, no maintenance finished product. Products maintain the highest tinting strength and color consistency from bag to bag. Each batch is custom formulated for each job. The color is conveniently packaged in a dissolvable sack that disperses rapidly into the batch.

Features / Chemical Makeup

Concrete colors contain only finely milled synthetic iron oxides, the strongest and most stable colors available. These colors are lime-proof, sun fast, inert, and meet or exceed the criteria of ASTM C979.

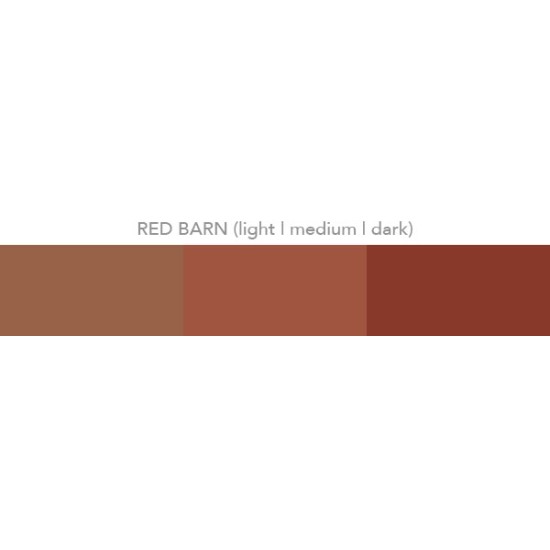

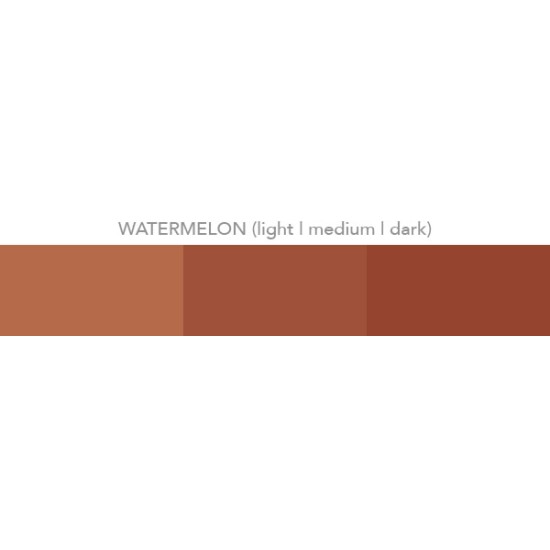

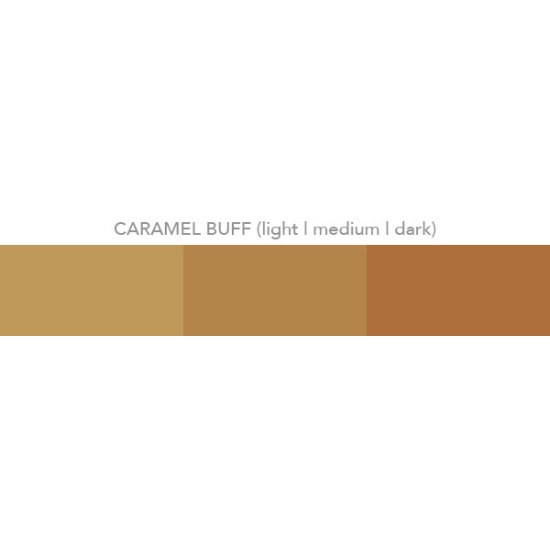

The colors cover the full color spectrum: brown, buff, tan, black, yellow, orange, red, green, blue, and white. Each color match is handled on an individual basis. In cases where exact color matching is required, samples of your field raw materials may be required for sample preparation.

Concrete colors are available in specially designed packages for your on-site use. Because of the inherent tinting strength of synthetic iron oxides, standard loadings do not exceed 4%. Levels greater than 5% will not enhance the finished color.

Concrete Mix Design

- Any type of Portland Cement may be used in colored concrete, however, due to cement's inherent properties; it is necessary to follow approved mixing practices.

- Cement for the entire job/project should be the same type and brand and from the same mill and plant.

- All aggregate, fine or coarse, should be supplied from one source and be non-reactive.

- The mix design should remain constant. If the cement content varies, the pigment content must be adjusted to maintain the weight ratio of pigment to cement.

- The concrete consistency as denoted by the slump test should not exceed 5". A 3" - 4" slump is recommended. Use the lowest slump - compatible with a workable and placeable mix.

- Always rinse the mixer drum thoroughly before batching colored concrete.

- The pigment amount to be added must be determined by weight. Never estimate by visual bag splitting.

- Add color by weight directly into the mixer along with the aggregate cement and water.

- The transit mixer should operate at charging or mixing speed (50 to 100 revolutions) for 5 to 10 minutes while adding color.

Additional Admixtures

Colors for integrally colored concrete contain no additives, allowing the concrete designer complete flexibility.

Products recommends using the admixtures that the ready-mix company stocks and has a proven experience record with their materials. The desired admixtures should be added separately at the batch plant.

Air-entraining admixtures are acceptable. Calcium Chloride is never recommended. Water reducing admixtures are acceptable.

Sub Grade

A successful concrete slab starts with a well-drained sub grade that can uniformly sustain the weight of the slab as well as the load imposed on the slab. The sub grade should be uniformly graded compacted and thoroughly dampened. There should not be any soft or muddy spots, or freestanding water on the sub grade.

Placing

Integral colored concrete does not require special procedures for placing and finishing, however greater care is recommended.

All colored concrete should be placed at the same slump, using the lowest slump consistent with a workable and placeable mix. A 3" - 4" slump is recommended, 5" maximum. Once a portion of the batch has been placed, no water should be added to the remaining batch. Concrete should always be placed in the forms as near the final location as possible. Movement should be minimal, as it encourages segregation. Be sure to cover all nearby slabs and structures to avoid spatters from the new colored concrete.

Finishing

For color uniformity finishing should be done carefully. Do not over trowel, as this will cause dark spots from trowel burning. Finishing must not begin until bleed water has left the surface to avoid serious scaling, dusting, crazing, efflorescence, or uneven coloring. No dusting of cement or sprinkling of fogging water should be used when finishing colored concrete. A broom, rotary, or textured finish is recommended.

Placement Of Vertical Concrete

Planning is crucial in placement of vertical and poured-in-place concrete. Consider type of cement, detailing of formwork, mixing and placing techniques, slump control, and temperature of cure. It is recommended that a field mock-up panel be prepared. Include all materials, reinforcing steel as in the finished product.

Design Criteria For Colored Concrete

The following points should be considered in designing colored concrete. The concrete temperature should be between 65 and 85 degrees. Timing of the arrival of concrete trucks is crucial so that there is no excessive mixing. Avoid using porous forming materials. Conveying methods must be consistent with ACT-304-73. The concrete should be deposited in the level lifts 12-18" thick. The distance between intersections should generally be about 18" depending on the concrete mix and vibrator used. Tilt-up concrete panels should be textured using sandblasting and surface retarders to expose coarse aggregate.

Patching Colored Concrete

Do repair work within two days to minimize color variation. The same materials and methods should be used. A 50/50 mix of white/gray cement can be used to compensate for the darker patch area. The same color loading should be used on all repairs.

For Central Mix Or Premixed Batch Plants

Add 1/2 (one-half) of the total batch into a clean ready mixed truck drum. Do not use slurry water or reclaimed aggregates. Add the correct number of disintegrating bags into the drum and mix at high speed for at least 3 minutes. Batch the remaining concrete into the truck and mix again for at least 3 minutes before final slump adjustment. At the job site, re-mix the load for at least 3 minutes to insure concrete consistency. Do not exceed maximum allowable revolutions.

Additional Considerations For Consistent Color

Color loads should never be smaller than 3 cubic yards. Add reinforcement fibers after the color load has been thoroughly mixed. This reduces the potential for fiber color balling.

Use one source for cement, aggregate and pozzolans throughout out the job. Monitor and control incoming material consistency. Do not use calcium chloride-based admixtures.

Wash out all drums before loading. Keep slumps consistent. Minimize driver-added water. A 3 to 5-inch slump is recommended. Maintain the same water/cement ratio. Required higher slumps should be achieved by using water reducing of plasticizing admixtures and NOT by adding water because this will adversely affect the color.