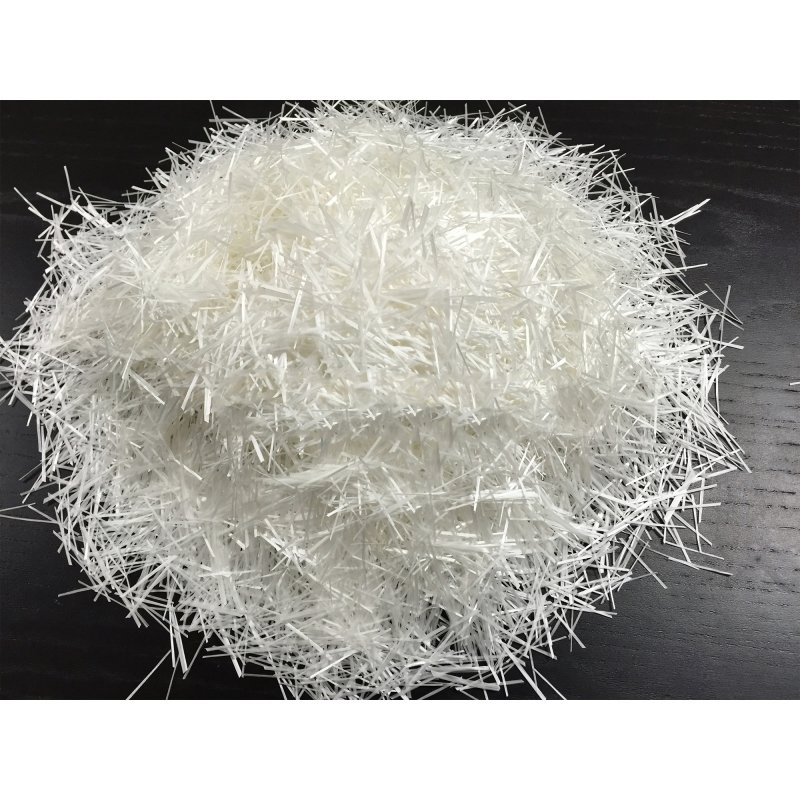

Alkali Resistant Glass Fiber Concrete Chopped Strands PH901X

Fibers for concrete cement countertops, AR Glass Fiber GFRC Chopped Strands 1 lb

PH901X AR Glass Fibers is the heaviest strands of the of the leading fibers manufacturer Nippon Electric Glass America Inc.

PH901X Fiber Strand contains 200 filaments. 18 microns diameter of the filament provides your GFRC with the highest integrity and the most resistance to filamentization during mixing and processing.

19% or higher zirconia content provides excellent fiber alkali resistance and acid resistance.

Suitable for spray-premix

Perfect for mortar and concrete reinforcement applications; all decorative applications as countertops, fireplace surrounds.

Manufactured by NEG America Inc., Japan in compliance with ASTM C1666/C 1666M, EN 15422 and under recommendations of PCI and GRCA.

Available in 13,19 and 25 mm (1/2", 3/4" and 1") length.

Packaging: 1 lb, 44 lb.

Frequently Asked Questions about ALKALI RESISTANT GLASS FIBERS

Q: If i grind to expose aggregate, will these glass fibers show in the surface?

A: It's so hard to stamp concrete with one flexible mat. You can use flexible mats, but I would recommend to use at least 3-5 mats.

Yes, glass fibers will show up on surface if you’ll grind concrete surface unless you mix two batches and line your mold with about 1/2 to 3/4 in of the batch without the glass fibers. Also depends if you are doing cast in place or inverted. You can also torch the the alkali resistant fibers after grinding.

Q: How much glass fiber i need for gfrc concrete countertop casting?

A: It really depends to your preferences or casted product, but average alkali resistant fibers to GFRC concrete ratio is between 1 to 3% by total concrete weight. For 100 lbs of GFRC concrete you need between 1 to 3 lbs of glass fibers. Always make a test prior casting actual product. Standard concrete ratio 1 1/2 to 3 lbs per cubic yard.