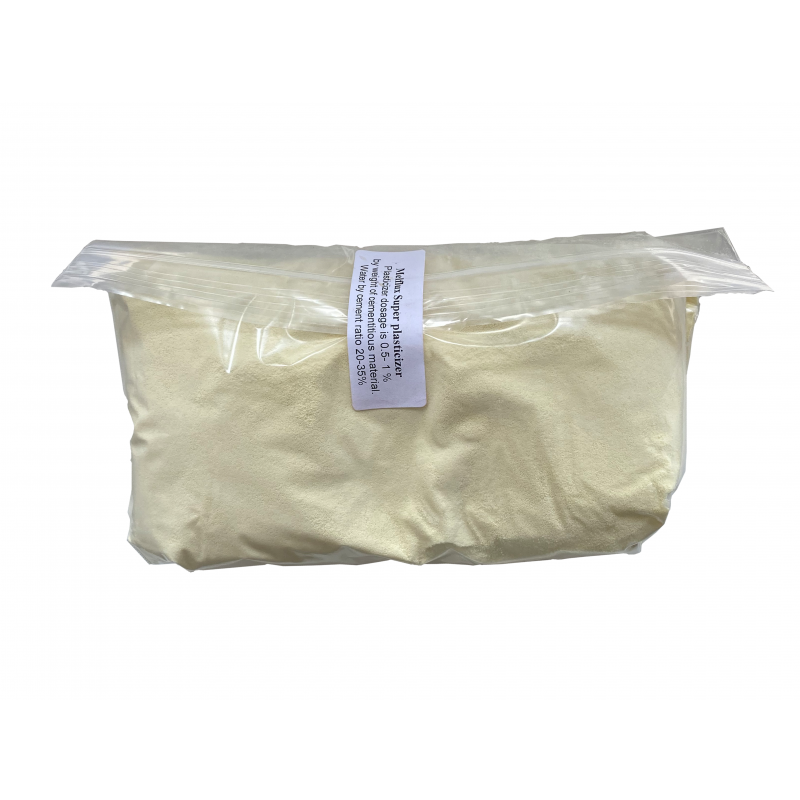

Concrete admixture - Water reducer - Super plasticizer. Melflux

Concrete admixture-Water reducer-Super plasticizer

High-performance superplasticizer for cement based construction materials

Super plasticizer provides an excellent development of early strength. Many important characteristics of concrete are influenced by the ratio (by weight) of water to cementitious materials (w/cm) used in the mixture. By reducing the amount of water. The cement paste will have higher density, which result in higher paste quality. An increase in paste quality will yield higher compressive and flexural strength, lower permeability, increase resistance to weathering, improve the bond of concrete and reinforcement, reduce the volume change from drying and wetting, and reduce shrinkage cracking tendencies.

How to mix with Cementitious Material: Mix concrete/cement with plasticizer for a few minutes, then add water (mix at least 3-5 minutes). You can also add Super plasticizer to the water 10-15 minutes prior to casting (until plasticizer dissolves in water), then mix with dry ingredients. Please note: Concrete minimum mixing time is 3 minutes with mechanical drill or 5 minutes with mortar mixer (it takes a few minutes until Super Plasticizer absorbs into the cement and start reaction).

Please note: Super plasticizer dosage rate calculated by Cement weight, not total concrete weight

Characteristics / Chemistry

Free-flowing, spray dried powder of modified polycarboxylic ether.

Fields of Application

Superplasticizer is especially optimized for plastification and water reduction of cementitious construction materials.

Superplasticizer provides an excellent development of early strength.

Fields of application are :

Self-levelling underlayments (SLU)

Feather-edge products

Non-shrink grouts

Cementitious floor screeds

Cementitious fast-setting floor screeds

Cementitious self-levelling floor screeds

Repair mortars

Injection mortars

Tile adhesives and joint fillers

Dry-mix concrete

Technical Data

Technical Data Sheet

| Physical shape | powder |

| Appearance | characteristic, yellowish to brownish |

| Drying loss, [%] | max. 2.0 |

| Bulk density, [kg/m3] | 300 to 600 |

| pH-value (20 °C), 20 % solution | 6.5 to 8.5 |

| Dosage recommendation, [%] by weight of cementitious material | 0.05 to 1.00 by Cement weight |

Further Technical Data

Superplasticizer based on latest polymer technology. These types of superplasticizers typically contain certain side chains based on polyethylene glycol. Due to raw material synthesis of the polyethylene glycol, the nature of radical polymerization and the composition, it is known that this technical product has some natural colour variations from nearly colourless to yellowish up to slightly brownish. However, these colour variations have no influence on the application performance of the product. It is not known that the product colour changes significantly over time under normal storage conditions.

Available Packaging

1lb. sample bag

33lb. paper bag

1650 lb. 50 paper bags(1 pallet)

Storage

Store in the original packaging (resealed if opened), dry (not exceeding 60% RH) and cool (not exceeding 40 °C / 104 °F); no double stacking; may cake when exposed to pressure and friction

Shelf life

1 year

How to mix Superplasticizer