Concrete sealers are specialized compounds used to protect concrete surfaces from moisture, oils, salts, and other harmful substances. They create a protective layer on the surface of the concrete, preventing damage and extending its lifespan. Sealers can also enhance the appearance of concrete, making it glossier or matte, depending on the type of sealer chosen.

For example, a parking lot owner might use concrete sealers to protect the concrete floor from water, oils, and salts, thus preventing damage and prolonging its service life.

These substances create a firm coating on top of the concrete surface

Sealers for concrete pavers:

1. Penetrative sealers – penetrate deeply into concrete pores and make its structure stronger from inside, preventing cracks appearing and erosion.

2. Acrylic sealers – create a protective layer on the concrete surface which doesn’t allow moisture and pollutants to get inside.

3. Polyurethane sealers – known for being highly resistant to mechanical damage and chemicals.

What concrete sealer is best?

We offer a wide range of sealers, including polyurethane, acrylic, and many more. If you need a countertop or other details tailored to your specific needs, contact us for a consultation. It's crucial to understand the differences between water-based and solvent-based sealers before making a decision, as they affect both price and characteristics.

Water-based sealers typically have a less pronounced odor compared to their solvent-based counterparts due to their lower volatile organic compound (VOC) content, making them generally more environmentally friendly. This makes them preferable for many people. On the other hand, solvent-based sealers, such as Solv and Bas Seal, tend to be more durable, especially under heavy loads.

Enhancing Color Effects

Another distinction lies in the color enhancement effects. Solvent-based sealers provide a full-color effect, intensifying the concrete's color as if water were poured on it. Water-based sealers can also enhance color, but usually not as vividly as solvent-based ones.

Why Seal Concrete?

Regardless of the chosen type (acrylic or water-based with solvent), the sealer must be properly cured to 100% for the concrete to ensure its longevity. Even concrete that feels dry to the touch may still be undergoing chemical reactions internally. The waiting time before sealing depends on specific conditions, such as the thickness and mass of the concrete. For thin layers, like coatings or similar materials, a wait of about seven days is sufficient. However, for concrete slabs, it is recommended to wait around 28 days before sealing.

Sealing concrete is crucial because if moisture remains under the concrete, it must evaporate somewhere. If this occurs through the concrete surface, it can lead to discoloration or even bubbling. Incorrect timing for sealing can result in problems that are difficult to fix.

As an option Cure and Seal sealer can be applied over fresh concrete. Cure and Seal CS-250 25% solids finishing membrane improves the curing process of freshly placed concrete and simultaneously provides protection. Upon application it forms a water–retaining film that beneficially restricts moisture loss that helps concrete reach its optimal cure and hardness. Therefore, this is an economical alternative to costly, time-consuming water curing.

It is a color enhancing, gloss coat helpful in preventing dusting, spalling, moisture and chemical migration through a slab and provides resistance to freeze/thaw cycles. It protects during the many steps of construction from incidental staining, UV protection, and abrasion resistance. CS250 improves any concrete upon placement: driveways and sidewalks, stamped concrete, exposed aggregate, pool decks, terrazzo, parking garages floors, or any other slab, whether industrial, commercial, or residential. This product should not be applied as a sealer for concrete overlay systems.

Instead of a curing agent and a sealer, CS-250 can be placed on the surface and then without removing it later, a new coating can be placed on top to give the substrate better protection.

CS 250 is not designed as a stand-alone sealer. After concrete has cured, for optimum performance, finished product should be sealed with solvent based sealers like HS-200.

Specialty Sealers for High Traffic and Decorative Effects

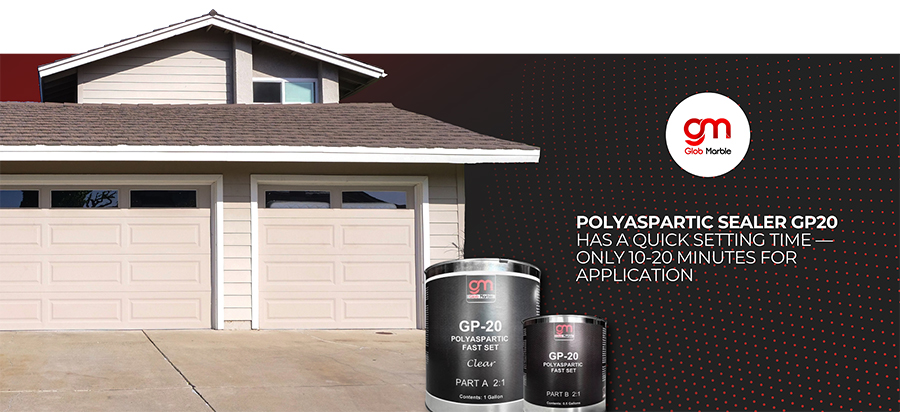

Polyaspartic sealers are designed for immediate use after application. They are known for their high strength and excellent resistance to tire marks, making them especially popular for garages where cars frequently enter and exit. For instance, our polyaspartic sealer GP20 has a quick setting time - only 10-20 minutes for application.

These sealers require expertise in application since they begin reacting and hardening very quickly. Therefore, we recommend using them only by experienced professionals or contractors to avoid application problems and achieve the desired results.

For homeowners and craftsmen who want to minimize risks and complete work quickly, sealers like GP20, PO, Spartik, GM offer significant advantages. Many store owners need to maintain their premises without downtime for concrete repairs, especially if the store opens at 7:00 AM.

For example, GP20 allows light foot traffic within 3-8 hours after application, depending on weather conditions. Polyurethane sealers, such as PU SP, provide high strength and a long working window, making them attractive for those who prefer not to rush.

If you want a more decorative effect, consider the G30 product, available in various shades and finishes, including matte, satin, and glossy. This product includes additives to improve adhesion, creating unique shades like orange.

What concrete sealer should I use?

Acrylic sealers, such as HS200, are usually the most affordable among all types of sealers. This makes them an excellent choice for large open areas like patios, driveways, and pool decks. They also provide good ventilation, which is crucial for exterior applications. Considering the potential for water to be trapped under concrete coverings during rain, acrylic sealers are often the preferred choice for outdoor areas. Polyurethane or polyaspartic options might not be as suitable under these conditions, even though they offer higher protection levels.

Countertop Sealers

Lastly, let’s talk about sealers for countertops. These are unique because they are typically polyurethane sealers that are FDA-approved for food contact. They are crucial for maintaining the health and safety of those who use the countertops. While they might be more expensive, their certification ensures that they are safe for food preparation areas.

It’s important to remember that countertop sealers have specific requirements different from floor sealers. Using the wrong sealer can lead to health risks, making it essential to choose products certified for food safety.

Conclusion

Selecting the right concrete sealer is essential for the longevity and appearance of your concrete surfaces. Whether you need a durable solution for a high-traffic garage or a food-safe option for countertops, understanding the types and proper application of sealers will ensure your project’s success. We provide a personalized approach to color selection and will create the exact color you decide on. Contact us for a consultation to find the best sealer for your needs.

Keep updated with our latest offerings and tips by following our YouTube channel and engaging with our community.

Where to buy concrete sealer?

Visit our website for details GlobMarble