The kitchen is a high-traffic area where countertops endure constant wear and tear. Regular surfaces can quickly become damaged from water, heat, and sharp objects. That’s why epoxy coatings are an ideal solution. These durable, chemically resistant materials not only safeguard surfaces but also enhance their appearance with a sleek, polished finish. Whether you’re a homeowner looking to upgrade your patio or a contractor seeking top-quality materials for a project, understanding how to apply epoxy coatings is essential.

Benefits of Epoxy Coatings

Epoxy coatings offer numerous advantages that make them an ideal choice for various surfaces:

- Durability and Resistance: Epoxy coatings are known for their ability to withstand heavy traffic and wear. They are highly resistant to chemicals, making them perfect for garages, workshops, and other areas where spills are common.

- Chemical and Stain Resistance: The non-porous nature of epoxy coatings means they are easy to clean and maintain. Spills can be wiped away without leaving stains, ensuring your surfaces remain pristine.

- Aesthetic Appeal: With a wide range of colors, textures, and finishes available, epoxy coatings can be customized to suit any style. Whether you prefer a glossy finish or a textured look, there’s an epoxy option for you.

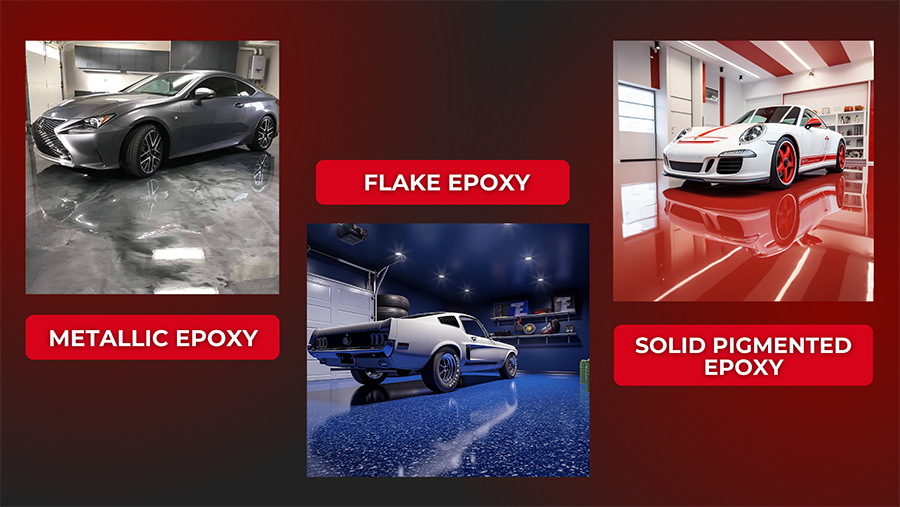

Metallic Epoxy and Garage Flake Epoxy: Choose Your Option

Metallic Epoxy: For a striking, modern look, metallic epoxy coatings are an excellent choice. These coatings feature metallic pigments that create a unique, glossy finish with depth and movement. They are perfect for high-traffic areas or spaces where you want to make a bold statement. Metallic epoxy is often used in showrooms, retail spaces, and luxury homes to add a touch of elegance and sophistication.

Garage Flake Epoxy: If you’re looking to enhance the durability and aesthetics of your garage floor, consider garage flake epoxy. This type of epoxy contains decorative flakes that provide a textured, colorful finish. The flakes help to hide imperfections and provide slip resistance, making it a practical choice for areas prone to spills and heavy use. Garage flake epoxy is ideal for garages, workshops, and any space where a functional yet visually appealing surface is desired.

Solid Pigmented Epoxy: For those who prefer a clean, uniform appearance with vibrant color, solid pigmented epoxy is an excellent option. This type of epoxy offers a rich, consistent color throughout the surface, providing a sleek and polished look. Solid pigmented epoxy is highly durable and resistant to chemicals and abrasions, making it ideal for industrial settings, commercial spaces, and even residential areas that demand both durability and a pop of color. Whether you want to create a professional workspace or add a bold, uninterrupted hue to your home, solid pigmented epoxy delivers both style and performance.

These specialized epoxy options offer both aesthetic appeal and functional benefits, making them a great addition to your flooring project. Ready to transform your space? Explore our selection of epoxy coatings to find the perfect solution for your needs.

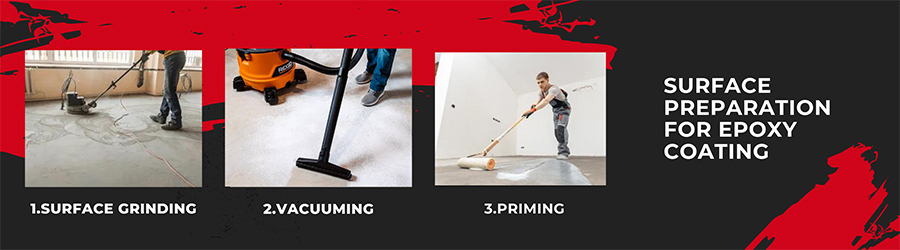

Surface Preparation for Epoxy Coating

Proper surface preparation is essential for achieving a smooth, long-lasting epoxy finish. Here are the key steps:

- Surface Grinding: Start by grinding the concrete floor to remove any surface contaminants that could prevent the epoxy from bonding properly. This process also helps to create a textured surface that enhances adhesion.

- Vacuuming: After grinding, thoroughly vacuum the surface to remove all dust and debris created during the grinding process. This step is essential for ensuring a clean surface that will allow the epoxy to adhere effectively.

- Priming: Finally, apply a primer to the prepared surface. Priming improves adhesion and further enhances the durability of the epoxy coating, ensuring a long-lasting finish.

How to Properly Apply Epoxy Coatings

Once the surface is prepared, it’s time to apply the epoxy coating. Follow these steps for a professional result:

- Mixing Components: Epoxy coatings consist of two parts: resin and hardener. It’s essential to mix these components thoroughly to ensure proper curing. Use a mixing paddle and follow the manufacturer’s instructions for the correct ratios.

- Application: Use a roller or brush to apply the epoxy evenly across the surface. Work in small sections to avoid streaks or uneven coverage. For larger areas, consider using an epoxy garage kit, which includes all the necessary tools and materials.

- Spreading and Leveling: To achieve a smooth finish, use a squeegee or roller to spread the epoxy evenly. Make sure to eliminate any bubbles or imperfections during this process.

- Drying Time: Allow the epoxy to cure according to the manufacturer’s instructions. The drying time can vary depending on temperature and humidity, so ensure the area is well-ventilated and undisturbed.

Care and Maintenance of Epoxy Coating

Proper care and maintenance will keep your epoxy-coated surfaces looking great for years:

- Cleaning: Regularly clean the surface with a mild detergent and water. Avoid using abrasive cleaners that could damage the epoxy.

- Preventing Damage: Place mats or protective pads under heavy objects to prevent scratches or dents. Avoid dragging sharp items across the surface.

- Regular Inspection: Periodically inspect the surface for any signs of wear or damage. Address any issues promptly to maintain the integrity of the coating.

Wrapping Up Your Epoxy Coating Project

With the right preparation and application techniques, epoxy coatings can transform any surface into a durable, attractive feature of your home or workspace. Ready to start your project? Visit our store to order high-quality epoxy coatings and get everything you need to achieve a professional finish.